| Mining Cable | |||

| Type W | Type G | Type G-GC | more |

![]() Mining Cable

Mining Cable

Type 240 1.1 to 11KV

Applications

Mining cables are mainly used as feeder cables for power supply to machinery or longwall supply.Minging cable

contains 3 large pilots and large core screens provide for low resistance earthing.

Standards

AS/NZS 1802:2003

AS/NZS 1125

AS/NZS 3808 AS/NZS 5000.1

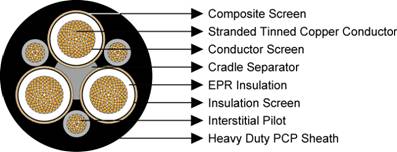

Construction

3×Conductors: Flexible stranded tinned annealed copper conductor.

Conductor Screen: 1.1/1.1kV - polyester barrier tape, 3.3/3.3kV andabove - polyester barrier tape and extruded

semiconductive tape.

Insulation: EPR.

Insulation Screen:Semiconductive tape.

Composite Screen (earth conductor):Tinned annealed copper braiding interwove with polyester yarn.

3×Interstitial Pilot:EPR covered flexible stranded tinned copper conductor.

Cradle Separator: Semiconductive PCP.

Sheath: Heavy duty PCP sheath. Dimensions and Weight

| Nominal Conductor Area | Strand Size | Insulation Thickness | Core screen | Pilot Conductor | Thickness of Sheath | Nominal Overall Diameter | Nominal Weight | ||

| Strand Size | Area of Screen | Strand Size | Thickness of Covering | ||||||

| mm² | No/mm | mm | No/mm | mm² | No/mm | mm | mm | mm | kg/100m |

| Type 240.1 | |||||||||

| 6 | 84/0.30 | 1.5 | 7/0.25 | 7.2 | 18/0.30 | 1.0 | 3.8 | 30.0 | 131 |

| 10 | 77/0.40 | 1.5 | 7/0.25 | 8.6 | 27/0.30 | 1.0 | 3.8 | 32.6 | 159 |

| 16 | 126/0.40 | 1.6 | 7/0.25 | 9.6 | 42/0.30 | 1.0 | 4.0 | 35.8 | 202 |

| 25 | 209/0.40 | 1.6 | 7/0.25 | 11.3 | 66/0.30 | 1.2 | 4.3 | 39.7 | 265 |

| 35 | 285/0.40 | 1.6 | 7/0.25 | 12.4 | 90/0.30 | 1.2 | 4.6 | 43.1 | 326 |

| 50 | 380/0.40 | 1.7 | 7/0.25 | 14.1 | 120/0.30 | 1.2 | 5.0 | 47.7 | 404 |

| 70 | 203/0.67 | 1.8 | 7/0.25 | 16.5 | 39/0.67 | 1.2 | 5.4 | 53.9 | 533 |

| 95 | 259/0.67 | 2.0 | 7/0.25 | 18.2 | 39/0.67 | 1.2 | 6.0 | 58.6 | 635 |

| 120 | 336/0.67 | 2.1 | 7/0.25 | 20.3 | 42/0.67 | 1.4 | 6.4 | 64.4 | 775 |

| 150 | 427/0.67 | 2.3 | 7/0.25 | 22.3 | 54/0.67 | 1.4 | 6.9 | 70.2 | 940 |

| 185 | 518/0.67 | 2.5 | 7/0.30 | 30.2 | 63/0.67 | 1.4 | 7.4 | 77.4 | 1150 |

| 240 | 672/0.67 | 2.8 | 7/0.30 | 33.6 | 77/0.67 | 1.6 | 8.2 | 86.0 | 1440 |

| 300 | 854/0.67 | 3.0 | 7/0.40 | 50.1 | 98/0.67 | 1.6 | 8.8 | 95.1 | 1810 |

| Type 240.3 | |||||||||

| 16 | 126/0.40 | 3.0 | 7/0.25 | 13.1 | 42/0.30 | 1.4 | 5.3 | 46.2 | 306 |

| 25 | 209/0.40 | 3.0 | 7/0.25 | 14.8 | 66/0.30 | 1.4 | 5.6 | 50.1 | 379 |

| 35 | 285/0.40 | 3.0 | 7/0.25 | 15.8 | 90/0.30 | 1.4 | 5.9 | 53.5 | 444 |

| 50 | 380/0.40 | 3.0 | 7/0.25 | 17.2 | 120/0.30 | 1.4 | 6.3 | 57.6 | 525 |

| 70 | 203/0.67 | 3.0 | 7/0.25 | 18.6 | 39/0.67 | 1.4 | 6.6 | 62.5 | 656 |

| 95 | 259/0.67 | 3.0 | 7/0.25 | 20.3 | 39/0.67 | 1.4 | 7.1 | 66.2 | 750 |

| 120 | 336/0.67 | 3.0 | 7/0.30 | 27.2 | 42/0.67 | 1.6 | 7.4 | 72.0 | 910 |

| 150 | 427/0.67 | 3.0 | 7/0.40 | 39.6 | 54/0.67 | 1.6 | 7.8 | 78.0 | 1115 |

| 185 | 518/0.67 | 3.0 | 7/0.40 | 42.2 | 63/0.67 | 1.8 | 8.2 | 83.4 | 1280 |

| 240 | 672/0.67 | 3.0 | 7/0.40 | 46.6 | 77/0.67 | 1.8 | 8.8 | 90.3 | 1540 |

| 300 | 854/0.67 | 3.0 | 7/0.50 | 63.2 | 98/0.67 | 1.8 | 9.4 | 98.4 | 1920 |

| Type 240.6 | |||||||||

| 16 | 126/0.40 | 5.0 | 7/0.25 | 17.2 | 42/0.30 | 1.4 | 6.4 | 57.3 | 440 |

| 25 | 209/0.40 | 5.0 | 7/0.25 | 18.6 | 66/0.30 | 1.4 | 6.7 | 61.2 | 521 |

| 35 | 285/0.40 | 5.0 | 7/0.25 | 18.6 | 90/0.30 | 1.6 | 7.0 | 64.6 | 593 |

| 50 | 380/0.40 | 5.0 | 7/0.25 | 21.3 | 120/0.30 | 1.6 | 7.3 | 68.5 | 685 |

| 70 | 203/0.67 | 5.0 | 7/0.25 | 23.4 | 39/0.67 | 1.6 | 7.7 | 73.7 | 830 |

| 95 | 259/0.67 | 5.0 | 7/0.30 | 29.2 | 39/0.67 | 1.6 | 8.1 | 77.8 | 954 |

| 120 | 336/0.67 | 5.0 | 7/0.30 | 31.7 | 42/0.67 | 1.8 | 8.5 | 83.1 | 1111 |

| 150 | 427/0.67 | 5.0 | 7/0.40 | 45.7 | 54/0.67 | 1.8 | 8.9 | 89.1 | 1335 |

| 185 | 518/0.67 | 5.0 | 7/0.40 | 48.4 | 63/0.67 | 1.8 | 9.3 | 94.5 | 1515 |

| 240 | 672/0.67 | 5.0 | 7/0.40 | 52.8 | 77/0.67 | 1.8 | 9.9 | 101.4 | 1810 |

| 300 | 854/0.67 | 5.0 | 7/0.50 | 71.5 | 98/0.67 | 1.8 | 10.4 | 109.3 | 2190 |

| Type 240.11 | |||||||||

| 25 | 209/0.40 | 7.6 | 7/0.25 | 23.7 | 66/0.30 | 2.0 | 8.1 | 75.6 | 752 |

| 35 | 285/0.40 | 7.6 | 7/0.30 | 30.2 | 90/0.30 | 2.0 | 8.4 | 79.7 | 860 |

| 50 | 380/0.40 | 7.6 | 7/0.30 | 31.7 | 120/0.30 | 2.0 | 8.7 | 83.6 | 961 |

| 70 | 203/0.67 | 7.6 | 7/0.30 | 34.1 | 39/0.67 | 2.0 | 9.1 | 88.8 | 1125 |

| 95 | 259/0.67 | 7.6 | 7/0.40 | 47.5 | 39/0.67 | 2.0 | 9.6 | 93.7 | 1300 |

| 120 | 336/0.67 | 7.6 | 7/0.40 | 51.0 | 42/0.67 | 2.2 | 9.9 | 98.8 | 1470 |

| 150 | 427/0.67 | 7.6 | 7/0.40 | 53.7 | 54/0.67 | 2.2 | 10.3 | 103.5 | 1659 |

| 185 | 518/0.67 | 7.6 | 7/0.40 |

57.2 |

63/0.67 |

2.2 |

10.7 | 108.8 | 1880 |