| BS 7211 Cables | |||

BS 7211 Cables

BS 7211 Cables

H05Z-U/H07Z-U

Application and Description

BS 7211 cables are designed for the internal wiring of switchboards and distributor boards with an alternating

nominal voltage up to 1000 Volts or a direct voltage up to 750 volts. Generally install in pipes or ducts and

internal wiring of appliances with maximum operating temperature of 90º C, and generally in areas (such as

public and government buildings) where smoke and toxic fumes may cause a threat to life and equipment. The

cables produce no corrosive gasses when burnt which is particularly important where electronic equipment is

installed.

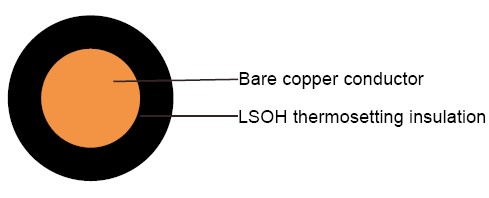

Cable Construction

Solid bare copper

single wire to IEC 60228 Cl-1

Cross-link polyolefin EI5 core insulation

LSOH - low smoke, zero halogen

Insulation Colour

Green/Yellow, Black, Blue, Brown, Red, White, Yellow, Grey, Violet

Technical Characteristics

Working voltage: 300/500v (H05Z-U), 450/750v (H07Z-U)

Test voltage: 2000 / 2500 volts

Flexing bending radius: 15 x Ø

Static bending radius: 10 x Ø

Flexing temperature: +5º C to +90º C

Short circuit temperature: +250º C

Insulation resistance: 10 MΩ x km

Flame retardant: IEC 60332.1

Smoke density acc. to EN 50268 / IEC 61034

Corrosiveness of combustion gases acc. to EN 50267-2-2, IEC 60754-2

Flame test: flame-retardant acc. to EN 50265-2-1, IEC 60332.1

Cable Parameter

| AWG | No. of Cores x Nominal Cross Sectional Area | Nominal Thickness of Insulation | Nominal Overall Diameter | Nominal CopperWeight | Nominal Weight | Minimum insulation resistance at 90 °C |

|---|---|---|---|---|---|---|

| # x mm² | mm | mm | kg/km | kg/km | MΩ·km | |

| H05Z-U | ||||||

| 20 | 1 x 0.5 | 0.6 | 1.9-2.4 | 4.8 | 8 | 0.015 |

| 18 | 1 x 0.75 | 0.6 | 2.1-2.6 | 7.2 | 12 | 0.012 |

| 17 | 1 x 1 | 0.6 | 2.2-2.8 | 9.6 | 14 | 0.011 |

| H07Z-U | ||||||

| 16 | 1 x 1.5 | 0.7 | 2.6-3.3 | 14.4 | 20 | 0.011 |

| 14 | 1 x 2.5 | 0.8 | 3.2-4.0 | 24 | 30 | 0.010 |

| 12 | 1 x 4 | 0.8 | 3.6-4.6 | 38 | 45 | 0.0085 |

| 10 | 1 x 6 | 0.8 | 4.1-5.2 | 58 | 65 | 0.0070 |

| 8 | 1 x 10 | 1.0 | 5.3-6.6 | 96 | 105 | 0.0070 |