| FIREGUARD Flame Retardant Cables | |||

Fire retardant cable(Fireguard)

Fire retardant cable(Fireguard)

600/1000V XLPE Insulated, PVC Sheathed, Armoured Power Cables to BS 5467 (2-5 Cores)

FGD400 1RVMV-R (CU/XLPE/PVC/SWA/PVC 600/1000V Class 2)

BS Code: 6942X/6943X/6944X/6945X

Application

The cables are mainly used in power stations, mass transit underground passenger systems, airports,

petrochemical plants, hotels, hospitals, and high-rise buildings. This product type is TUV approved.

Standards

Basic design to BS 5467

Approvals

TUV Certification (Z1 17 01 98200 003)

Fire Performance

| Flame Retardance (Single Vertical Wire Test) | BS EN 60332-1-2 |

|---|

Voltage Rating

600/1000V

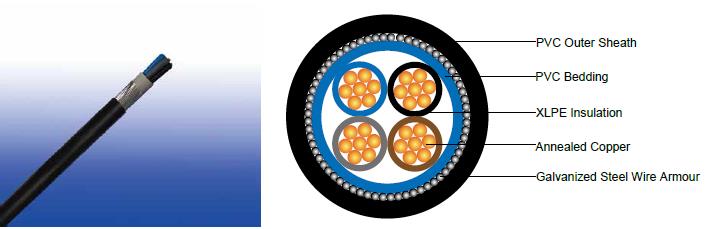

Cable Construction

Conductor :Annealed copper wire, stranded according to BS EN 60228 class 2.

Insulation:Extruded XLPE GP 8 according to BS 7655-1.3.

Bedding:PVC.

Armouring:Galvanized steel wire

Outer Sheath:PVC Type 9 according to BS 7655-4.2.

Outer Sheath Option:UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite

properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3,UL

1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can

also be provided upon request.

Colour Code

| Insulation Colour | Two-core: Brown, blue |

|---|---|

Sheath Colour |

Black, other colours can be offered upon request. |

Physical AND THERMAL PROPERTIES

| Maximum temperature range during operation (XLPE) | 90°C |

|---|---|

Maximum short circuit temperature (5 Seconds) |

250°C |

Minimum bending radius |

8 x overall diameter |

Construction Parameters

| Conductor | FGD400 1RVMV-R |

||||||

|---|---|---|---|---|---|---|---|

No. of Cores x Cross Section |

Class of Conductor |

Nominal Insulation |

Nominal Bedding |

Nominal Armour Wire |

Nominal Sheath Thickness |

Approx. Overall Diameter |

Approx. Weight |

No.xmm² |

|

mm |

mm |

mm |

mm |

mm |

kg/km |

2 Cores |

|||||||

2x1.5a |

2 |

0.6 |

0.8 |

0.9 |

1.3 |

12.1 |

320 |

2x2.5a |

2 |

0.7 |

0.8 |

0.9 |

1.4 |

13.6 |

365 |

2x4.0a |

2 |

0.7 |

0.8 |

0.9 |

1.4 |

14.7 |

440 |

2x6.0a |

2 |

0.7 |

0.8 |

0.9 |

1.4 |

15.9 |

470 |

2x10a |

2 |

0.7 |

0.8 |

0.9 |

1.5 |

18.0 |

800 |

2x16a |

2 |

0.7 |

0.8 |

1.25 |

1.5 |

20.4 |

900 |

2x25b |

2 |

0.9 |

0.8 |

1.25 |

1.6 |

20.4 |

1240 |

2x25a |

2 |

0.9 |

0.8 |

1.25 |

1.6 |

24.1 |

1240 |

2x35b |

2 |

0.9 |

1.0 |

1.6 |

1.7 |

23.3 |

1710 |

2x35a |

2 |

0.9 |

1.0 |

1.6 |

1.7 |

27.7 |

1710 |

2x50b |

2 |

1.0 |

1.0 |

1.6 |

1.8 |

25.8 |

1800 |

2x70b |

2 |

1.1 |

1.0 |

1.6 |

1.9 |

29.0 |

2320 |

2x95b |

2 |

1.1 |

1.2 |

2.0 |

2.0 |

33.1 |

3150 |

2x120b |

2 |

1.2 |

1.2 |

2.0 |

2.1 |

36.1 |

3880 |

2x150b |

2 |

1.4 |

1.2 |

2.0 |

2.2 |

39.3 |

4820 |

2x185b |

2 |

1.6 |

1.4 |

2.5 |

2.4 |

44.7 |

5920 |

2x240b |

2 |

1.7 |

1.4 |

2.5 |

2.5 |

49.0 |

7300 |

2x300b |

2 |

1.8 |

1.6 |

2.5 |

2.6 |

53.5 |

8770 |

2x400b |

2 |

2.0 |

1.6 |

2.5 |

2.8 |

59.0 |

10905 |

3 Cores |

|||||||

3x1.5a |

2 |

0.6 |

0.8 |

0.9 |

1.3 |

12.6 |

340 |

3x2.5a |

2 |

0.7 |

0.8 |

0.9 |

1.4 |

14.1 |

408 |

3x4.0a |

2 |

0.7 |

0.8 |

0.9 |

1.4 |

15.3 |

498 |

3x6.0a |

2 |

0.7 |

0.8 |

0.9 |

1.4 |

16.6 |

600 |

3x10a |

2 |

0.7 |

0.8 |

1.25 |

1.5 |

19.5 |

915 |

3x16a |

2 |

0.7 |

0.8 |

1.25 |

1.6 |

21.6 |

1130 |

3x25a |

2 |

0.9 |

1.0 |

1.6 |

1.7 |

26.7 |

1710 |

3x25b |

2 |

0.9 |

1.0 |

1.6 |

1.7 |

23.6 |

1710 |

3x35a |

2 |

0.9 |

1.0 |

1.6 |

1.8 |

29.4 |

2100 |

3x35b |

2 |

0.9 |

1.0 |

1.6 |

1.8 |

25.7 |

2100 |

3x50b |

2 |

1.0 |

1.0 |

1.6 |

1.8 |

28.5 |

2450 |

3x70b |

2 |

1.1 |

1.0 |

1.6 |

1.9 |

32.2 |

3120 |

3x95b |

2 |

1.1 |

1.2 |

2.0 |

2.1 |

37.0 |

4310 |

3x120b |

2 |

1.2 |

1.2 |

2.0 |

2.2 |

40.4 |

5160 |

3x150b |

2 |

1.4 |

1.4 |

2.5 |

2.3 |

45.5 |

7160 |

3x185b |

2 |

1.6 |

1.4 |

2.5 |

2.4 |

49.8 |

8600 |

3x240b |

2 |

1.7 |

1.4 |

2.5 |

2.6 |

55.1 |

10755 |

3x300b |

2 |

1.8 |

1.6 |

2.5 |

2.7 |

60.2 |

13080 |

3x400b |

2 |

2.0 |

1.6 |

2.5 |

2.9 |

66.6 |

15810 |

4 Cores |

|

|

|

|

|

|

|

4x1.5a |

2 |

0.6 |

0.8 |

0.9 |

1.3 |

13.3 |

390 |

4x2.5a |

2 |

0.7 |

0.8 |

0.9 |

1.4 |

15.0 |

470 |

4x4.0a |

2 |

0.7 |

0.8 |

0.9 |

1.4 |

16.4 |

580 |

4x6.0a |

2 |

0.7 |

0.8 |

1.25 |

1.5 |

18.7 |

805 |

4x10a |

2 |

0.7 |

0.8 |

1.25 |

1.5 |

21.1 |

1090 |

4x16a |

2 |

0.7 |

0.8 |

1.25 |

1.6 |

23.4 |

1320 |

4x25a |

2 |

0.9 |

1.0 |

1.6 |

1.7 |

28.9 |

1840 |

4x25b |

2 |

0.9 |

1.0 |

1.6 |

1.7 |

26.1 |

1840 |

4x35a |

2 |

0.9 |

10 |

1.6 |

1.8 |

31.9 |

2310 |

4x35b |

2 |

0.9 |

1.0 |

1.6 |

1.8 |

28.6 |

2310 |

4x50b |

2 |

1.0 |

1.0 |

1.6 |

1.9 |

32.0 |

2970 |

4x70b |

2 |

1.1 |

1.2 |

2.0 |

2.1 |

37.7 |

4240 |

4x95b |

2 |

1.1 |

1.2 |

2.0 |

2.2 |

41.7 |

5400 |

4x120b |

2 |

1.2 |

1.4 |

2.5 |

2.3 |

47.1 |

7000 |

4x150b |

2 |

1.4 |

1.4 |

2.5 |

2.4 |

51.4 |

8350 |

4x185b |

2 |

1.6 |

1.4 |

2.5 |

2.6 |

56.6 |

10130 |

4x240b |

2 |

1.7 |

1.6 |

2.5 |

2.7 |

63.0 |

12840 |

4x300b |

2 |

1.8 |

1.6 |

2.5 |

2.9 |

68.8 |

15530 |

4x400b |

2 |

2.0 |

1.8 |

3.15 |

3.2 |

78.1 |

19950 |

5 Cores |

|||||||

5x1.5a |

2 |

0.6 |

0.8 |

0.9 |

1.4 |

14.3 |

430 |

5x2.5a |

2 |

0.7 |

0.8 |

0.9 |

1.4 |

16.1 |

545 |

5x4.0a |

2 |

0.7 |

0.8 |

0.9 |

1.5 |

17.8 |

680 |

5x6.0a |

2 |

0.7 |

0.8 |

1.25 |

1.5 |

20 |

840 |

5x10a |

2 |

0.7 |

0.8 |

1.25 |

1.6 |

22.9 |

1105 |

5x16a |

2 |

0.7 |

1.0 |

1.6 |

1.7 |

26.6 |

1450 |

5x25a |

2 |

0.9 |

1.0 |

1.6 |

1.8 |

31.5 |

2245 |

5x35a |

2 |

0.9 |

1.0 |

1.6 |

1.9 |

34.8 |

2840 |

5x50a |

2 |

1.0 |

1.2 |

2.0 |

2.0 |

40.4 |

3895 |

5x70a |

2 |

1.1 |

1.2 |

2.0 |

2.2 |

46.3 |

5145 |

a Circular or compacted circular stranded conductors (class 2).

b Shaped stranded conductor (class 2).

ELECTRICAL PROPERTIES

| Conductor Operating Temperature | 90°C |

|---|---|

Ambient Temperature |

30°C |

Current-Carrying Capacities (Amp) according to BS7671:2008 table 4E4A

Conductor crosssectional area |

Reference Method C (clipped direct) |

Reference Method E (in free air |

Reference Method D (direct in in |

|||

|---|---|---|---|---|---|---|

1 two-core cable*, |

1 three-or four |

1 two-core |

1 three-or four |

1 two-core cable*, |

1 three-or four |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

mm2 |

A |

A |

A |

A |

A |

A |

1.5 |

27 |

23 |

29 |

25 |

25 |

21 |

2.5 |

36 |

31 |

39 |

33 |

33 |

28 |

4.0 |

49 |

42 |

52 |

44 |

43 |

36 |

6.0 |

62 |

53 |

66 |

56 |

53 |

44 |

10 |

85 |

73 |

90 |

78 |

71 |

58 |

16 |

110 |

94 |

115 |

99 |

91 |

75 |

25 |

146 |

124 |

152 |

131 |

116 |

96 |

35 |

180 |

154 |

188 |

162 |

139 |

115 |

50 |

219 |

187 |

228 |

197 |

164 |

135 |

70 |

279 |

238 |

291 |

251 |

203 |

167 |

95 |

338 |

289 |

354 |

304 |

239 |

197 |

120 |

392 |

335 |

410 |

353 |

271 |

223 |

150 |

451 |

386 |

472 |

406 |

306 |

251 |

185 |

515 |

441 |

539 |

463 |

343 |

281 |

240 |

607 |

520 |

636 |

546 |

395 |

324 |

300 |

698 |

599 |

732 |

628 |

446 |

365 |

400 |

787 |

673 |

847 |

728 |

- |

- |

Voltage Drop (Per Amp Per Meter) according to BS7671:2008 table 4E4B

Conductor cross- sectional area |

Two-core cables, d.c. |

Two-core cable, single-phase a.c. |

Three-or four core cable, three-phase a.c. |

||||

|---|---|---|---|---|---|---|---|

1 |

2 |

3 |

4 |

||||

mm2 |

mV/A/m |

mV/A/m |

mV/A/m |

||||

1.5 |

31 |

31 |

27 |

||||

2.5 |

19 |

19 |

16 |

||||

4.0 |

12 |

12 |

10 |

||||

6.0 |

7.9 |

7.9 |

6.8 |

||||

10 |

4.7 |

4.7 |

4.0 |

||||

16 |

2.9 |

2.9 |

2.5 |

||||

|

|

r |

x |

z |

r |

x |

z |

25 |

1.85 |

1.85 |

0.160 |

1.90 |

1.60 |

0.140 |

1.65 |

35 |

1.35 |

1.35 |

0.155 |

1.35 |

1.15 |

0.135 |

1.15 |

50 |

0.98 |

0.99 |

0.155 |

1.00 |

0.86 |

0.135 |

0.87 |

70 |

0.67 |

0.67 |

0.150 |

0.69 |

0.59 |

0.130 |

0.60 |

95 |

0.49 |

0.50 |

0.150 |

0.52 |

0.43 |

0.130 |

0.45 |

120 |

0.39 |

0.40 |

0.145 |

0.42 |

0.34 |

0.130 |

0.37 |

150 |

0.31 |

0.32 |

0.145 |

0.35 |

0.38 |

0.125 |

0.30 |

185 |

0.25 |

0.26 |

0.145 |

0.29 |

0.22 |

0.125 |

0.26 |

240 |

0.195 |

0.200 |

0.140 |

0.24 |

0.175 |

0.125 |

0.21 |

300 |

0.155 |

0.160 |

0.140 |

0.21 |

0.140 |

0.120 |

0.185 |

400 |

0.120 |

0.130 |

0.140 |

0.190 |

0.115 |

0.120 |

0.165 |

Note: *Spacings larger than one cable diameter will result in a large voltage drop.

r = conductor resistance at operating temperature

x = reactance

z = impedance