| Firetox Flame Retardant Cables | |||

Firetox Flame Retardant Cables

Firetox Flame Retardant Cables

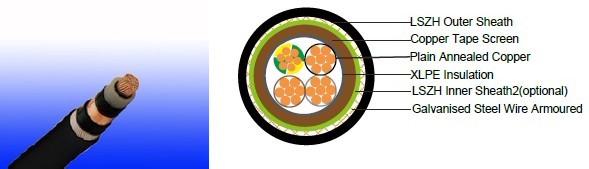

600/1000V XLPE Insulated, LSZH Sheathed, Screened Power Cables (4cores)

FTX400 1RCZ1MZ1-R (CU/XLPE/CUTO/LSZH/SWA/LSZH 600/1000V Class 2)

APPLICATION

This cable is designed specifi cally to suit the broad spectrum of requirements of Variable Speed Drives and also

include features for reducing the transmission of electromagnetic interference. This range of screened cables

drastically reduce interferences from electrical noise, especially in Variable Speed Drive (VSD) applications and

are manufactured with fixed conductors. With shield conductivity of 1/10th of phase conductor conductivity, this

range of VSD cables effectively restrain radiated and conducted radio-frequency emissions.

STANDARDS

Basic design to IEC 60502-1

FIRE PERFORMANCE

Flame Retardance (Single Vertical Wire Test) |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1 ; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2- 1*; DIN VDE 0482-265-2-1* |

|---|---|

Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30- 004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2- 4 |

| Halogen Free | IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1* |

No Corrosive Gas Emission |

IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

minimum Smoke Emission |

IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268- 1&2*; BS 7622-1&2* |

| No Toxic gases | NES 02-713; NF C 20-454 |

Note: Asterisk * denotes superseded standard.

VOLTAGE RATING

600/1000V

CABLE CONSTRUCTION

Conductor: Plain annealed copper wire, stranded according to IEC(EN) 60228 class 2.

Insulation: Extruded cross-linked XLPE compound.

Inner sheath1: LSZH Compound

Screen: Copper Tape

Inner sheath2: LSZH Compound

Armouring: Galvanised Steel Wire

Outer Sheath: Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1 (Thermosetting LSZH compound

type SW2-SW4 as per BS 7655-2.6 can be offered.)

COLOUR CODE

Insulation colour as per bs7671

| with earth conductor | without earth conductor | |

|---|---|---|

| 2Cores | - | Brown,Blue |

| 3Cores | Yellow/Green,Brown,Blue | Brown,Gray,Black |

| 4Cores | Yellow/Green,Brown,Gray,Black | Brown,Gray,Black,Blue |

| 5Cores | Yellow/Green,Brown,Gray,Black,Blue | Brown,Gray,Black,Blue,Black |

| above 5 Cores | Yellow/Green,Black Numbered | Black Numbered |

sheath colour: Black

Physical AND THERMAL PROPERTIES

Temperature range during operation: Max.90°C for XLPE

250°C in short-circuit for 5s max.

Minimum bending radius: 12 x Overall Diameter (for 1.5mm2 to 300mm2)

CONSTRUCTION PARAMETERS

| Conductor | FTX400 1RCZ1MZ1-R | |||||||

|---|---|---|---|---|---|---|---|---|

| No. of Core X Cross Section |

No./ Nominal Diameter of Strands |

Nominal Insulation Thickness |

Nominal Sheath Thickness |

Diameter Under Screen |

Diameter Over Inner Sheath |

Armour Wire Diameter |

Nominal Overall Diameter |

Approx. Weight |

| mm2 | No./mm | mm | mm | mm | mm | mm | mm | kg/km |

| 4x1.5 | 7/0.53 | 0.7 | 1.8 | 9.7 | 12.1 | 13.9 | 17.7 | 640 |

| 4x2.5 | 7/0.67 | 0.7 | 1.8 | 10.7 | 13.1 | 14.9 | 18.7 | 730 |

| 4x4 | 7/0.85 | 0.7 | 1.8 | 12.0 | 14.4 | 16.2 | 20.0 | 870 |

| 4x6 | 7/1.04 | 0.7 | 1.8 | 13.4 | 15.8 | 18.3 | 22.1 | 1180 |

| 4x10 | 7/1.35 | 0.7 | 1.8 | 15.6 | 18.0 | 20.5 | 24.3 | 1490 |

| 4x16 | 7/1.70 | 0.7 | 1.8 | 18.1 | 20.5 | 23.7 | 27.5 | 2070 |

| 4x25 | 7/2.14 | 0.9 | 1.8 | 22.3 | 24.1 | 27.3 | 31.1 | 2790 |

| 4x35(S) | 7/2.52 | 0.9 | 1.8 | 25.0 | 26.8 | 30.0 | 33.8 | 2940 |

| 4x50(S) | 19/1.78 | 1.0 | 2.0 | 27.8 | 29.6 | 32.8 | 37.0 | 3500 |

| 4x70(S) | 19/2.14 | 1.1 | 2.2 | 31.6 | 33.4 | 37.4 | 42.0 | 5000 |

| 4x95(S) | 19/2.52 | 1.1 | 2.3 | 35.4 | 37.2 | 41.2 | 46.0 | 6300 |

| 4x120(S) | 37/2.03 | 1.2 | 2.5 | 39.0 | 40.8 | 45.8 | 51.0 | 8200 |

| 4x150(S) | 37/2.25 | 1.4 | 2.6 | 42.0 | 43.8 | 48.8 | 54.2 | 9600 |

| 4x185(S) | 37/2.52 | 1.6 | 2.8 | 47.8 | 49.6 | 54.6 | 60.4 | 11500 |

| 4x240(S) | 61/2.25 | 1.7 | 3.0 | 54.0 | 55.8 | 60.8 | 67.0 | 14400 |

| 4x300(S) | 61/2.52 | 1.8 | 3.0 | 58.0 | 59.8 | 64.8 | 71.4 | 17200 |

Electrical PROPERTIES

Conductor Operating Temperature : 90°C

Ambient Temperature : 30°C

Current-Carrying Capacities (Amp)

| Conductor crosssectional area |

Reference Method 1 (clipped direct) |

Reference Method 11 (on a perforated horizontal cable trayor Reference Method 13 [free air] ) |

In single-way ducts |

Laid direct in ground |

||||

|---|---|---|---|---|---|---|---|---|

| one 2-core cable single phase a.c. or d.c. |

one 3-core or 4-core cable 3-phase a.c. |

one 2-core cable single phase a.c. or d.c. |

one 3-core or 4-core cable 3-phase a.c. |

one 2-core cable single phase a.c. or d.c. |

one 3-core or 4-core cable 3-phase a.c. |

one 2-core cable single phase a.c. or d.c. |

one 3-core or 4-core cable 3-phase a.c. |

|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| mm2 | A | A | A | A | A | A | A | A |

| 1.5 | 27 | 23 | 29 | 25 | - | 23 | - | 28 |

| 2.5 | 36 | 31 | 39 | 33 | - | 30 | - | 36 |

| 4 | 49 | 42 | 52 | 44 | - | 40 | - | 48 |

| 6 | 62 | 53 | 66 | 56 | - | 50 | - | 60 |

| 10 | 85 | 73 | 90 | 78 | - | 65 | - | 80 |

| 16 | 110 | 94 | 115 | 99 | 115 | 94 | 140 | 115 |

| 25 | 146 | 124 | 152 | 131 | 145 | 125 | 180 | 150 |

| 35 | 180 | 154 | 188 | 162 | 175 | 150 | 215 | 180 |

| 50 | 219 | 187 | 228 | 197 | 210 | 175 | 255 | 215 |

| 70 | 279 | 238 | 291 | 251 | 260 | 215 | 315 | 265 |

| 95 | 338 | 289 | 354 | 304 | 310 | 260 | 380 | 315 |

| 120 | 392 | 335 | 410 | 353 | 355 | 300 | 430 | 360 |

| 150 | 451 | 386 | 472 | 406 | 400 | 335 | 480 | 405 |

| 185 | 515 | 441 | 539 | 463 | 455 | 380 | 540 | 460 |

| 240 | 607 | 520 | 636 | 546 | 520 | 440 | 630 | 530 |

| 300 | 698 | 599 | 732 | 628 | 590 | 495 | 700 | 590 |

Voltage Drop (Per Amp Per Meter)

| Conductor cross- sectional area | 2-core cable d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, 3-phase a.c. | 2 cables, single-phase a.c. | 3 or 4 cables, 3-phase a.c. |

||||

|---|---|---|---|---|---|---|---|---|---|

| In ducts or in ground | In ducts or in ground | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | ||||

| mm2 | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | ||||

| 1.5 | 31.0 | 31.0 | 27.0 | 31.0 | 25.0 | ||||

| 2.5 | 19.0 | 19.0 | 16.0 | 19.0 | 15.0 | ||||

| 4 | 12.0 | 12.0 | 10.0 | 12.0 | 9.7 | ||||

| 6 | 7.9 | 7.9 | 6.8 | 7.9 | 6.5 | ||||

| 10 | 4.7 | 4.7 | 4.0 | 4.7 | 3.9 | ||||

| 16 | 2.9 | 2.9 | 2.5 | 2.9 | 2.6 | ||||

| r | x | z | r | x | z | ||||

| 25 | 1.850 | 1.350 | 0.160 | 1.900 | 1.600 | 0.140 | 1.650 | 1.900 | 1.600 |

| 35 | 1.350 | 1.350 | 0.155 | 1.350 | 1.150 | 0.135 | 1.150 | 1.350 | 1.200 |

| 50 | 0.980 | 0.990 | 0.155 | 1.000 | 0.860 | 0.135 | 0.870 | 1.000 | 0.870 |

| 70 | 0.670 | 0.670 | 0.150 | 0.690 | 0.590 | 0.130 | 0.600 | 0.690 | 0.610 |

| 95 | 0.490 | 0.500 | 0.150 | 0.520 | 0.430 | 0.130 | 0.450 | 0.520 | 0.450 |

| 120 | 0.390 | 0.400 | 0.145 | 0.420 | 0.340 | 0.130 | 0.370 | 0.420 | 0.360 |

| 150 | 0.310 | 0.320 | 0.145 | 0.350 | 0.280 | 0.125 | 0.300 | 0.350 | 0.300 |

| 185 | 0.250 | 0.260 | 0.145 | 0.290 | 0.220 | 0.125 | 0.260 | 0.290 | 0.250 |

| 240 | 0.195 | 0.200 | 0.140 | 0.240 | 0.175 | 0.125 | 0.210 | 0.240 | 0.210 |

| 300 | 0.155 | 0.160 | 0.140 | 0.210 | 0.140 | 0.120 | 0.185 | 0.210 | 0.190 |