| Firetox Flame Retardant Cables | |||

Firetox Flame Retardant Cables

Firetox Flame Retardant Cables

600/1000V XLPE Insulated, LSZH Sheathed Power Cables to IEC 60502-1 (2-5 Cores & Multicore)

FTX400 1RZ1-R (CU/XLPE/LSZH 600/1000V Class 2)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports,

petrochemical plants, hotels, hospitals and high-rise buildings. This product type is CE approved.

STANDARDS

Basic design to IEC 60502-1

FIRE PERFORMANCE

| Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

|---|---|

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) |

IEC 60332-3-24; EN 60332-3-24 |

Halogen Free |

IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission |

IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission |

IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

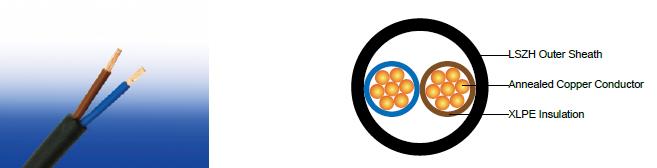

CABLE CONSTRUCTION

Conductor : The conductors shall be class 2 plain or metal-coated annealed copper in accordance with IEC

60228. Class 1 and class 5 conductor can be offered as option.

Insulation : Thermosetting XLPE material and thickness shall be as per IEC 60502-1.

Outer Sheath : Thermoplastic halogen free compound ST8 as per IEC 60502-1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite

properties can be offered as option.

COLOUR CODE

Insulation Colour |

2-core |

Brown and blue. |

|---|---|---|

3-core |

Brown, black and grey. |

|

4-core |

Blue, brown black and grey. |

|

5-core |

Green and yellow, blue, brown black, grey. |

|

Above 5 Cores |

Black cores with white numerals. |

|

Other colours can be offered upon request. |

||

Sheath Colour |

Black; other colours can be offered upon request. |

|

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius :

circular copper conductors OD≤25mm : 4 × Overall Diameter

circular copper conductors OD﹥25mm : 6 × Overall Diameter

shaped copper conductors : 8 × Overall Diameter

CONSTRUCTION PARAMETERS

| Conductor | FTX400 1RZ1-R |

|||||

|---|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area |

Conductor Class |

Nominal Insulation Thickness |

Nominal Sheath Thickness |

Approx. Overall Diameter |

Approx. Weight |

|

No.×mm² |

|

mm |

mm |

mm |

kg/km |

|

2 Cores |

||||||

2×1.5 |

2 |

0.7 |

1.8 |

9.2 |

117 |

|

2×2.5 |

2 |

0.7 |

1.8 |

10.0 |

146 |

|

2×4 |

2 |

0.7 |

1.8 |

11.0 |

190 |

|

2×6 |

2 |

0.7 |

1.8 |

12.0 |

244 |

|

2×10 |

2 |

0.7 |

1.8 |

13.6 |

349 |

|

2×16 |

2 |

0.7 |

1.8 |

15.4 |

495 |

|

2×25 |

2 |

0.9 |

1.8 |

18.4 |

735 |

|

2×35 |

2 |

0.9 |

1.8 |

20.6 |

963 |

|

2×50 |

2 |

1.0 |

1.8 |

23.6 |

1261 |

|

2×70 |

2 |

1.1 |

1.8 |

26.8 |

1751 |

|

2×95 |

2 |

1.1 |

1.9 |

30.2 |

2359 |

|

2×120 |

2 |

1.2 |

2.0 |

33.7 |

2950 |

|

2×150 |

2 |

1.4 |

2.2 |

37.5 |

3633 |

|

2×185 |

2 |

1.6 |

2.3 |

41.6 |

4523 |

|

2×240 |

2 |

1.7 |

2.5 |

46.7 |

5877 |

|

2×300 |

2 |

1.8 |

2.6 |

51.4 |

7285 |

|

2×400 |

2 |

2 |

2.9 |

58.9 |

9294 |

|

3 cores |

||||||

3×1.5 |

2 |

0.7 |

1.8 |

9.6 |

143 |

|

3×2.5 |

2 |

0.7 |

1.8 |

10.5 |

183 |

|

3×4 |

2 |

0.7 |

1.8 |

11.6 |

244 |

|

3×6 |

2 |

0.7 |

1.8 |

12.6 |

321 |

|

3×10 |

2 |

0.7 |

1.8 |

14.4 |

472 |

|

3×16 |

2 |

0.7 |

1.8 |

16.3 |

681 |

|

3×25 |

2 |

0.9 |

1.8 |

19.5 |

1027 |

|

3×35 |

2 |

0.9 |

1.8 |

21.9 |

1360 |

|

3×50 |

2 |

1.0 |

1.8 |

25.1 |

1795 |

|

3×70 |

2 |

1.1 |

1.9 |

28.7 |

2530 |

|

3×95 |

2 |

1.1 |

2.0 |

32.4 |

3441 |

|

3×120 |

2 |

1.2 |

2.1 |

36.1 |

4307 |

|

3×150 |

2 |

1.4 |

2.3 |

40.3 |

5276 |

|

3×185 |

2 |

1.6 |

2.4 |

44.6 |

6607 |

|

3×240 |

2 |

1.7 |

2.6 |

50.2 |

8593 |

|

3×300 |

2 |

1.8 |

2.7 |

55.2 |

10668 |

|

3×400 |

2 |

2.0 |

3.0 |

63.3 |

13570 |

|

3 cores + 1 core earth conductor |

||||||

|

|

3 cores |

1 core |

|

|

|

3×16/10 |

2 |

0.7 |

0.7 |

1.8 |

18.3 |

792 |

3×25/16 |

2 |

0.9 |

0.7 |

1.8 |

22.1 |

1201 |

3×35/16 |

2 |

0.9 |

0.7 |

1.8 |

24.7 |

1533 |

3×50/25 |

2 |

1.0 |

0.9 |

1.8 |

28.2 |

2069 |

3×70/35 |

2 |

1.1 |

0.9 |

2.0 |

33.1 |

2906 |

3×95/50 |

2 |

1.1 |

1.0 |

2.1 |

37.6 |

3949 |

3×120/70 |

2 |

1.2 |

1.1 |

2.3 |

42.0 |

5036 |

3×150/70 |

2 |

1.4 |

1.1 |

2.4 |

46.6 |

6005 |

3×185/95 |

2 |

1.6 |

1.1 |

2.6 |

52.2 |

7608 |

3×240/120 |

2 |

1.7 |

1.2 |

2.8 |

59.0 |

9856 |

3×300/150 |

2 |

1.8 |

1.4 |

3.0 |

65.2 |

12224 |

3×400/185 |

2 |

2.0 |

1.6 |

3.2 |

73.2 |

15523 |

4 cores |

||||||

4×1.5 |

2 |

0.7 |

1.8 |

10.4 |

172 |

|

4×2.5 |

2 |

0.7 |

1.8 |

11.3 |

223 |

|

4×4 |

2 |

0.7 |

1.8 |

12.5 |

303 |

|

4×6 |

2 |

0.7 |

1.8 |

13.7 |

402 |

|

4×10 |

2 |

0.7 |

1.8 |

15.7 |

599 |

|

4×16 |

2 |

0.7 |

1.8 |

17.5 |

873 |

|

4×25 |

2 |

0.9 |

1.8 |

21.2 |

1328 |

|

4×35 |

2 |

0.9 |

1.8 |

23.8 |

1767 |

|

4×50 |

2 |

1.0 |

1.8 |

27.5 |

2339 |

|

4×70 |

2 |

1.1 |

2.0 |

31.7 |

3326 |

|

4×95 |

2 |

1.1 |

2.1 |

35.8 |

4505 |

|

4×120 |

2 |

1.2 |

2.3 |

39.9 |

5669 |

|

4×150 |

2 |

1.4 |

2.4 |

44.6 |

6948 |

|

4×185 |

2 |

1.6 |

2.6 |

49.5 |

8701 |

|

4×240 |

2 |

1.7 |

2.8 |

55.7 |

11322 |

|

4×300 |

2 |

1.8 |

3.0 |

61.4 |

14105 |

|

4×400 |

2 |

2.0 |

3.2 |

70.4 |

17943 |

|

Multicore |

||||||

5×1.5 |

2 |

0.7 |

1.8 |

11.7 |

212 |

|

5×2.5 |

2 |

0.7 |

1.8 |

12.8 |

276 |

|

7×1.5 |

2 |

0.7 |

1.8 |

12.6 |

264 |

|

7×2.5 |

2 |

0.7 |

1.8 |

13.8 |

351 |

|

10×1.5 |

2 |

0.7 |

1.8 |

15.6 |

360 |

|

10×2.5 |

2 |

0.7 |

1.8 |

17.2 |

483 |

|

12×1.5 |

2 |

0.7 |

1.8 |

16.0 |

408 |

|

12×2.5 |

2 |

0.7 |

1.8 |

17.8 |

552 |

|

14×1.5 |

2 |

0.7 |

1.8 |

17.0 |

459 |

|

14×2.5 |

2 |

0.7 |

1.8 |

18.7 |

626 |

|

19×1.5 |

2 |

0.7 |

1.8 |

18.6 |

585 |

|

19×2.5 |

2 |

0.7 |

1.8 |

20.7 |

806 |

|

21×1.5 |

2 |

0.7 |

1.8 |

19.4 |

638 |

|

21×2.5 |

2 |

0.7 |

1.8 |

21.7 |

881 |

|

24×1.5 |

2 |

0.7 |

1.8 |

21.5 |

724 |

|

24×2.5 |

2 |

0.7 |

1.8 |

24.1 |

1002 |

|

30×1.5 |

2 |

0.7 |

1.8 |

22.8 |

866 |

|

30×2.5 |

2 |

0.7 |

1.8 |

25.5 |

1209 |

|

40×1.5 |

2 |

0.7 |

1.8 |

25.4 |

1108 |

|

40×2.5 |

2 |

0.7 |

1.9 |

28.7 |

1560 |

|

48×1.5 |

2 |

0.7 |

1.8 |

28.0 |

1307 |

|

48×2.5 |

2 |

0.7 |

1.9 |

31.6 |

1864 |

|

61×1.5 |

2 |

0.7 |

1.9 |

30.7 |

1631 |

|

61×2.5 |

2 |

0.7 |

2.0 |

34.7 |

2312 |

|

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Ambient temperature : 30°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E2A

Conductor cross-sectional area |

Ref. Method A (enclosed in conduit in thermally insulating wall etc.) |

Ref. Method B (enclosed in conduit on a wall or in trunking etc.) |

Ref. Method C (clipped direct) |

Ref. Method E (in free air or on a perforated cable tray etc. horizontal or vertical) |

||||

1 two-core cable*, single-phase a.c. or d.c. |

1 three- or four-core cable*, three-phase a.c. |

1 two-core cable*, single-phase a.c. or d.c. |

1 three- or four-core cable*, three-phase a.c. |

1 two-core cable*, single-phase a.c. or d.c. |

1 three- or four-core cable*, three-phase a.c. |

1 two-core cable*, single-phase a.c. or d.c. |

1 three- or four-core cable*, three-phase a.c. |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

mm² |

A |

A |

A |

A |

A |

A |

A |

A |

1.5 |

18.5 |

16.5 |

22 |

19.5 |

24 |

22 |

26 |

23 |

2.5 |

25 |

22 |

30 |

26 |

33 |

30 |

36 |

32 |

4 |

33 |

30 |

40 |

35 |

45 |

40 |

49 |

42 |

6 |

42 |

38 |

51 |

44 |

58 |

52 |

63 |

54 |

10 |

57 |

51 |

69 |

60 |

80 |

71 |

86 |

75 |

16 |

76 |

68 |

91 |

80 |

107 |

96 |

115 |

100 |

25 |

99 |

89 |

119 |

105 |

138 |

119 |

149 |

127 |

35 |

121 |

109 |

146 |

128 |

171 |

147 |

185 |

158 |

50 |

145 |

130 |

175 |

154 |

209 |

179 |

225 |

192 |

70 |

183 |

164 |

221 |

194 |

269 |

229 |

289 |

246 |

95 |

220 |

197 |

265 |

233 |

328 |

278 |

352 |

298 |

120 |

253 |

227 |

305 |

268 |

382 |

322 |

410 |

346 |

150 |

290 |

259 |

334 |

300 |

441 |

371 |

473 |

399 |

185 |

329 |

295 |

384 |

340 |

506 |

424 |

542 |

456 |

240 |

386 |

346 |

459 |

398 |

599 |

500 |

641 |

538 |

300 |

442 |

396 |

532 |

455 |

693 |

576 |

741 |

621 |

400 |

- |

- |

625 |

536 |

803 |

667 |

865 |

741 |

Note: With or without a protective conductor.

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4E2B

Conductor cross-sectional area |

Two-core cable, d.c. |

Two-core cable, single-phase a.c. |

Three- or four-core cable, three-phase a.c. |

||||

1 |

2 |

3 |

4 |

||||

mm² |

mV/A/m |

mV/A/m |

mV/A/m |

||||

1.5 |

31 |

31 |

27 |

||||

2.5 |

19 |

19 |

16 |

||||

4 |

12 |

12 |

10 |

||||

6 |

7.9 |

7.9 |

6.8 |

||||

10 |

4.7 |

4.7 |

4.0 |

||||

16 |

2.9 |

2.9 |

2.5 |

||||

|

|

r |

x |

z |

r |

x |

z |

25 |

1.85 |

1.85 |

0.160 |

1.90 |

1.60 |

0.140 |

1.65 |

35 |

1.35 |

1.35 |

0.155 |

1.35 |

1.15 |

0.135 |

1.15 |

50 |

0.98 |

0.99 |

0.155 |

1.00 |

0.86 |

0.135 |

0.87 |

70 |

0.67 |

0.67 |

0.150 |

0.69 |

0.59 |

0.130 |

0.60 |

95 |

0.49 |

0.50 |

0.150 |

0.52 |

0.43 |

0.130 |

0.45 |

120 |

0.39 |

0.40 |

0.145 |

0.42 |

0.34 |

0.130 |

0.37 |

150 |

0.31 |

0.32 |

0.145 |

0.35 |

0.28 |

0.125 |

0.30 |

185 |

0.25 |

0.26 |

0.145 |

0.29 |

0.22 |

0.125 |

0.26 |

240 |

0.195 |

0.200 |

0.140 |

0.24 |

0.175 |

0.125 |

0.21 |

300 |

0.155 |

0.160 |

0.140 |

0.21 |

0.140 |

0.120 |

0.185 |

400 |

0.120 |

0.130 |

0.140 |

0.190 |

0.115 |

0.120 |

0.165 |

Note :

r = conductor resistance at operating temperature

x = reactance

z = impedance