| Marine Cables | |||

| MariTox Marine Flame Retardant Medium Voltage Cables | MariTox Marine Flame Retardant Power & Control Cables | MariFlex Marine Fire Resistant Power & Control Cables | other |

Water Blocked

Water Blocked

P2 or P2/P9 RFOU/TFOU 3.6/6KV

Applications

Marine cables are partially water blocked, flame retardant, low smoke, halogen free and mud resistant, used for

fixed installation for medium voltage power.

Standards

IEC 60092-353

IEC 60092-360

IEC 60332-1

IEC 60332-3-22

IEC 60754-1,2

IEC 61034-1,2

NEK 606

VG 95218 part 29

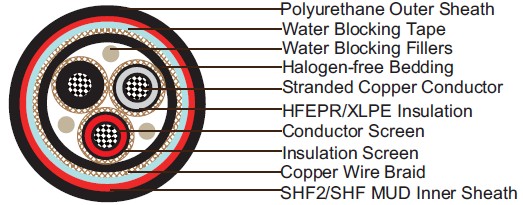

Construction

-

Conductors: Circular tinned annealed stranded copper to IEC 60228 class 2.

-

Conductor Screen: Semi conducting material.

-

Insulation: Halogen-free EPR. XLPE can be offered as an option (for TFOU cable).

-

Insulation Screen: Semi conducting material and tinned copper wire braid.

-

Filler: Water blocking fillers, if required.

-

Bedding: Halogen free compound, PETP wrapping tape will be applied over the bedding, if required.

-

Armour: Tinned copper wire braid, PETP wrapping tape will be applied over the braiding, if required.

-

Water Blocking Elements: Water blocking tape and strings for providing longitudinal water tightness.

-

Inner Sheath: Halogen free thermosetting compound, SHF2 (for TYPE P2), or halogen free mud resistant

-

thermosetting compound, SHF MUD (for TYPE P2/P9), coloured red.

-

Outer Sheath: Polyurethane for providing transversal water tightness, PE is optional,but can not meet low

-

smoke standard.

Electrical Characteristics

-

Nominal Cross Section Area mm² 16 25 35 50 70 95 120 Nominal Conductor Diameter mm 5.1 6.5 7.4 8.7 10.3 12.2 13.8 Maximum DC Resistant@20℃ Ω/km 1.16 0.734 0.529 0.391 0.27 0.195 0.154 Continuous Current Rating@45℃1 Core A 96 127 157 196 242 293 339 Continuous Current Rating@45℃3 Core A 67 89 110 137 169 205 237 Short Circuit Current 1s A 2290 3580 5010 7150 10020 13590 17170 Operating Voltage KV 3.6/6 3.6/6 3.6/6 3.6/6 3.6/6 3.6/6 3.6/6

Nominal Cross Section Area mm² 150 185 240 300 400 500 630 Nominal Conductor Diameter mm 15.1 17.0 19.6 21.9 24.6 27.6 32.5 Maximum DC Resistant@20℃ Ω/km 0.126 0.1 0.0762 0.0607 0.0475 0.0369 0.0286 Continuous Current Rating@45℃1 Core A 389 444 522 601 690 780 890 Continuous Current Rating@45℃3 Core A 272 311 365 421 483 546 623 Short Circuit Current 1s A 21460 26470 34340 42930 57230 71540 90140 Operating Voltage KV 3.6/6 3.6/6 3.6/6 3.6/6 3.6/6 3.6/6 3.6/6

Ambient Temperature Correction Factors

-

Ambient Temperature Correction Factors 35 40 45 50 55 60 65 70 75 80 Rating Factor 1.1 1.05 1.0 0.94 0.88 0.82 0.74 0.67 0.58 0.47

Mechanical and Thermal Properties

Bending Radius :15×OD (during installation); 9×OD (fixed installed).

Temperature Range : -20℃ ~ +90℃

Dimensions and Weight

Construction No. of cores×Cross section mm² |

Nominal Insulation Thickness mm |

Nominal BeddingThickness mm |

NominalInner Sheath Thickness mm |

NominalOuter Sheath Thickness mm |

||

|---|---|---|---|---|---|---|

Nominal Overall Diameter mm |

Nominal Weight kg/km |

|||||

| 1×16 | 2.5 | 1.4 | 1.1 | 1 | 24.8±2 | 819 |

| 1×25 | 2.5 | 1.5 | 1.1 | 1.2 | 26.4±2 | 1071 |

| 1×35 | 2.5 | 1.5 | 1.2 | 1.2 | 27.5±2 | 1213 |

| 1×50 | 2.5 | 1.6 | 1.2 | 1.2 | 28.7±2 | 1386 |

| 1×70 | 2.5 | 1.6 | 1.3 | 1.2 | 30.6±2 | 1675 |

| 1×95 | 2.5 | 1.7 | 1.3 | 1.4 | 32.8±2 | 2000 |

| 1×120 | 2.5 | 1.8 | 1.4 | 1.4 | 34.6±2 | 2347 |

| 1×150 | 2.5 | 1.8 | 1.4 | 1.4 | 36.3±2 | 2678 |

| 1×185 | 2.5 | 1.9 | 1.5 | 1.4 | 38.0±2 | 3166 |

| 1×240 | 2.6 | 2 | 1.5 | 1.6 | 42.0±2 | 3911 |

| 1×300 | 2.8 | 2.1 | 1.6 | 1.6 | 45.5±2 | 4856 |

| 1×400 | 3 | 2.2 | 1.7 | 1.6 | 49.8±2 | 5691 |

| 1×500 | 3.2 | 2.4 | 1.8 | 1.6 | 54.0±2 | 6941 |

| 1×630 | 3.2 | 2.5 | 1.9 | 1.6 | 58.3±2 | 8579 |

| 3×16 | 2.5 | 2.2 | 1.6 | 1 | 46.9±2 | 3077 |

| 3×25 | 2.5 | 2.3 | 1.7 | 1.2 | 47.8±2 | 3560 |

| 3×35 | 2.5 | 2.4 | 1.8 | 1.2 | 50.0±2 | 4011 |

| 3×50 | 2.5 | 2.5 | 1.9 | 1.2 | 53.3±2 | 4720 |

| 3×70 | 2.5 | 2.7 | 2 | 1.2 | 57.2±2 | 5864 |

| 3×95 | 2.5 | 2.8 | 2.1 | 1.4 | 61.7±2 | 7103 |

| 3×120 | 2.5 | 3 | 2.2 | 1.4 | 66.3±2 | 8573 |

| 3×150 | 2.5 | 3.1 | 2.3 | 1.4 | 70.2±2 | 9970 |

| 3×185 | 2.5 | 3.3 | 2.4 | 1.4 | 78.6±2 | 11193 |

| 3×240 | 2.6 | 3.5 | 2.5 | 1.6 | 85.5±2 | 12243 |

| 3×300 | 2.8 | 3.8 | 2.7 | 1.6 | 92.5±2 | 13587 |