| Mining Cable | |||

| Type W | Type G | Type G-GC | more |

Mining Cable

Mining Cable

H07RN-F/A07RN-F 450/750V Harmonized Rubber Cables

Applications

These cables are designed for the connection of heating units,industrial tools, mobile equipmentand machines,

e.g. vulcanisation plates,hand-operated equipment,transportable motors etc., undernormal mechanical loads in

dry anddamp areas, outdoors and in explosionhazard areas, as well as in industrialand agricultural applications

and onbuilding sites.

Standards

DIN VDE 0282 Part1 and Part 4

HD 22.1

HD 22.4

Construction

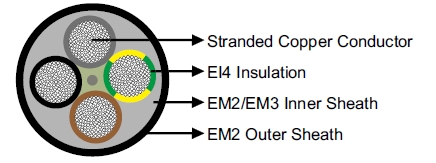

Conductors: Strandedcopper conductor, class 5 according to DIN VDE 0295/HD 383 S2.

Insulation: Rubbertype EI4 according to DIN VDE 0282 Part 1/HD 22.1.

Inner Sheath(for ≥ 10 mm² ormore than 5 cores): NR/SBR rubbertype EM1.

Outer Sheath: CR/PCP rubber type EM2.

Dimensions and Weight:

| Number of Cores×Nominal Cross Section | Insulation Thickness | Thickness of Inner Sheath | Thickness of Outer Sheath | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|---|---|---|

| No.×mm² | mm | mm | mm | mm | mm | kg/km |

| 1×1.5 | 0.8 | - | 1.4 | 5.7 | 6.7 | 60 |

| 2×1.5 | 0.8 | - | 1.5 | 8.5 | 10.5 | 120 |

| 3G1.5 | 0.8 | - | 1.6 | 9.2 | 11.2 | 170 |

| 4G1.5 | 0.8 | - | 1.7 | 10.2 | 12.5 | 210 |

| 5G1.5 | 0.8 | - | 1.8 | 11.2 | 13.5 | 260 |

| 7G1.5 | 0.8 | 1.0 | 1.6 | 14.0 | 17.0 | 360 |

| 12G1.5 | 0.8 | 1.2 | 1.7 | 17.6 | 20.5 | 515 |

| 19G1.5 | 0.8 | 1.4 | 2.1 | 20.7 | 26.3 | 795 |

| 24G1.5 | 0.8 | 1.4 | 2.1 | 24.3 | 28.5 | 920 |

| 1×2.5 | 0.9 | - | 1.4 | 6.3 | 7.5 | 75 |

| 2×2.5 | 0.9 | - | 1.7 | 10.2 | 12.5 | 170 |

| 3G2.5 | 0.9 | - | 1.8 | 10.9 | 13.0 | 230 |

| 4G2.5 | 0.9 | - | 1.9 | 12.1 | 14.5 | 290 |

| 5G2.5 | 0.9 | - | 2.0 | 13.3 | 16.0 | 360 |

| 7G2.5 | 0.9 | 1.1 | 1.7 | 17.0 | 20.0 | 510 |

| 12G2.5 | 0.9 | 1.2 | 1.9 | 20.6 | 23.5 | 740 |

| 19G2.5 | 0.9 | 1.5 | 2.2 | 24.4 | 30.9 | 1190 |

| 24G2.5 | 0.9 | 1.6 | 2.3 | 28.8 | 33.0 | 1525 |

| 1×4 | 1.0 | - | 1.5 | 7.2 | 8.5 | 100 |

| 2×4 | 1.0 | - | 1.8 | 11.8 | 14.5 | 195 |

| 3G4 | 1.0 | - | 1.9 | 12.7 | 15.0 | 305 |

| 4G4 | 1.0 | - | 2.0 | 14.0 | 17.0 | 400 |

| 5G4 | 1.0 | - | 2.2 | 15.6 | 19.0 | 505 |

| 1×6 | 1.0 | - | 1.6 | 7.9 | 9.5 | 130 |

| 2×6 | 1.0 | - | 2.0 | 13.1 | 16.0 | 285 |

| 3G6 | 1.0 | - | 2.1 | 14.1 | 17.0 | 380 |

| 4G6 | 1.0 | - | 2.3 | 15.7 | 19.0 | 550 |

| 5G6 | 1.0 | - | 2.5 | 17.5 | 21.0 | 660 |

| 1×10 | 1.2 | - | 1.8 | 9.5 | 11.5 | 195 |

| 2×10 | 1.2 | 1.2 | 1.9 | 17.7 | 21.5 | 565 |

| 3G10 | 1.2 | 1.3 | 2.0 | 19.1 | 22.5 | 715 |

| 4G10 | 1.2 | 1.4 | 2.0 | 20.9 | 24.5 | 875 |

| 5G10 | 1.2 | 1.4 | 2.2 | 22.9 | 27.0 | 1095 |

| 1×16 | 1.2 | - | 1.9 | 10.8 | 13.0 | 280 |

| 2×16 | 1.2 | 1.3 | 2.0 | 20.2 | 23.5 | 795 |

| 3G16 | 1.2 | 1.4 | 2.1 | 21.8 | 25.5 | 1040 |

| 4G16 | 1.2 | 1.4 | 2.2 | 23.8 | 28.0 | 1280 |

| 5G16 | 1.2 | 1.5 | 2.4 | 26.4 | 31.0 | 1610 |

| 1×25 | 1.4 | - | 2.0 | 12.7 | 15.0 | 405 |

| 4G25 | 1.4 | 1.6 | 2.2 | 28.9 | 33.0 | 1890 |

| 5G25 | 1.4 | 1.7 | 2.7 | 32.0 | 36.0 | 2335 |

| 1×35 | 1.4 | - | 2.2 | 14.3 | 17.0 | 545 |

| 4G35 | 1.4 | 1.7 | 2.7 | 32.5 | 36.5 | 2505 |

| 5G35 | 1.4 | 1.8 | 2.8 | 35.0 | 39.5 | 2718 |

| 1×50 | 1.6 | - | 2.4 | 16.5 | 19.5 | 730 |

| 4G50 | 1.6 | 1.9 | 2.9 | 37.7 | 42.0 | 3350 |

| 5G50 | 1.6 | 2.1 | 3.1 | 41.0 | 46.0 | 3804 |

| 1×70 | 1.6 | - | 2.6 | 18.6 | 22.0 | 955 |

| 4G70 | 1.6 | 2.0 | 3.2 | 42.7 | 47.0 | 4785 |

| 1×95 | 1.8 | - | 2.8 | 20.8 | 24.0 | 1135 |

| 4G95 | 1.8 | 2.3 | 3.6 | 48.4 | 54.0 | 6090 |

| 1×120 | 1.8 | - | 3.0 | 22.8 | 26.5 | 1560 |

| 4G120 | 1.8 | 2.4 | 3.6 | 53.0 | 59.0 | 7550 |

| 5G120 | 1.8 | 2.8 | 4.0 | 59.0 | 65.0 | 8290 |

| 1×150 | 2.0 | - | 3.2 | 25.2 | 29.0 | 1925 |

| 4G150 | 2.0 | 2.6 | 3.9 | 58.0 | 64.0 | 8495 |

| 1×185 | 2.2 | - | 3.4 | 27.6 | 31.5 | 2230 |

| 4G185 | 2.2 | 2.8 | 4.2 | 64.0 | 71.0 | 9850 |

| 1×240 | 2.4 | - | 3.5 | 30.6 | 35.0 | 2945 |

| 1×300 | 2.6 | - | 3.6 | 33.5 | 38.0 | 3495 |

| 1×630 | 3.0 | - | 4.1 | 45.5 | 51.0 | 7020 |