| Telephone Cables | ||||||||||||

|

||||||||||||

PE Insulated & LSZH Sheathed Cables to CW 1600

PE Insulated & LSZH Sheathed Cables to CW 1600

Application

The cables are similar in design and application to CW 1308, but with Low Smoke Halogen Free cores and

sheath. CW 1600 has the added advantage of an Aluminium/Polyester foil screen and drain wire. A fire barrier

tape is included on cable with more than 6 pairs. The cables are used for the internal wiring of building when the

need to protect people and equipment from smoke and fumes is paramount. The cables are designed to handle

low frequency signals for short range applications and intended to be terminated in insulation displacement

connectors (IDC).

Standards

CW 1600

Construction

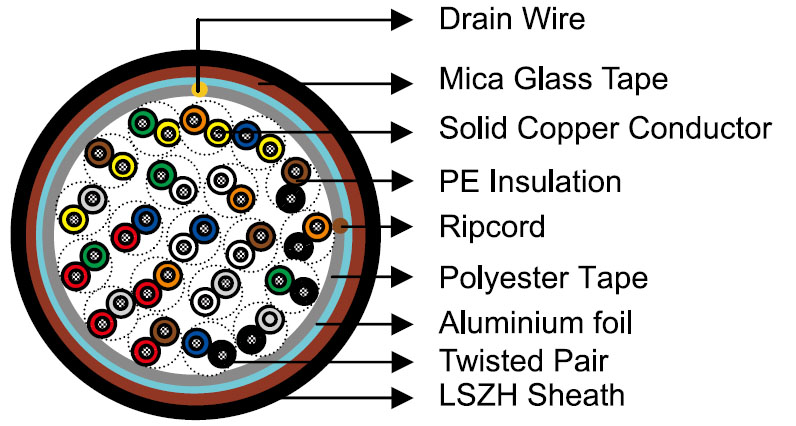

Conductors

Solid annealed bare or tinned copper sized 0.5mm (24AWG respectively) as per class 1 of BS 6360/IEC 60228.

Insulation

Solid polyethylene as per BS 6234/IEC 60708

Twisted Pairs

Insulated conductors are twisted into pairs with varying lay length to minimize crosstalk

Cabling Element

Twisted Pairs/Triples/Quads

Cable Core Assembly

There are two modes of construction: layer for general use, including two cables for installation in customer’s

premises where a good appearance is required; and unit of 20 pairs which includes an insulated earth conductor

of 1.38mm, for use with customer distribution scheme.

Core Wrapping

Cable containing more than 12 wires have a polyester tape applied over the cable core prior to sheathing.

Screen

A 24μ aluminium polyester foil shield can be provided for fully enclosing the core with an overlap

Fire Barrier Tape

Mica glass tape is included in cable with more than 6 pairs for achieving the required fire properties

Sheath

LSZH compound. Grey, White, Cream or Black colours are available for options

Ripcord

Nylon ripcord may be placed parallel to the cores to facilitate sheath removal

Drain Wire

A solid tinned 0.5mm earth/continuity wire shall be laid longitudinally

Electrical & Mechanical Properties

| Nominal Conductor Diameter | mm | 0.5 | 1.38 |

|---|---|---|---|

| Conductor Size | mm2 | 0.196 | 1.495 |

| Maximum Conductor Resistance @20°C | Ω/km | 97.8 | 12.4 |

| Minimum Insulation Resistance @500V DC | MΩ.km | 50 | N/A |

| Maximum Average Mutual Capacitance @0.8KHz-3.0KHz | nF/km | 80 | N/A |

| Maximum Capacitance Unbalance @0.8KHz-3.0KHz pair-to-pair | pF/500m | 500 | N/A |

| Minimum Insulation Thickness | mm | 0.15 | 0.55 |

| Maximum Insulated Conductor Diameter | mm | 0.95 | 3.5 |

Mechanical and Thermal Properties

Temperature range during operation (fixed state): -30°C – +70°C

Temperature range during installation (mobile state): -20°C – +50°C

Minimum bending radius: 7.5 x Overall Diameter

Fire Hazard Performance

| 1) Minimum Smoke Emission | IEC 61034, EN 50268 ( New: EN 61034), VDE 0482-268 ( New: VDE 0482-1034) These standards specify a method to measure the generation of smoke from cables during fire. The result is expressed as percentage of light transmitted. Usually, the smoke density shall not be less than 60%. |

|---|---|

| 2) Halogen Free | IEC 60754-1, EN 50267-2-1 These standards specify a method for determination of the amount of halogen acid gas evolved during combustion of compound. The hydrochloric acid yield should be less than 0.5%. |

| 3) Non corrosive gases | IEC 60754-2, EN 50267-2-2, VDE 0482-267 These standards specify a method for determination of acidity of gas evolved during combustion of cables by measuring PH and conductivity. The specimen is deemed to pass this test if the pH value is less than 4.3 when related to 1 litre of water and conductivity is less than 10 μs/min. |

| 4) Reduced Fire Propagation | IEC 60332-3C, EN 50266-2-4, VDE 0482-266-2-4 These standards specify a method for flame propagation test for bunched cables. |

| 5) Flame Retardancy | IEC 60332-1, VDE 0482-265-2-1 These standards specify a method for flame propagation test for single core cables. |

| 6) Temperature Index | BS EN ISO 4589-3, BS 2782 Part 1 These standards specify a method for measuring the temperature Index of materials. The temperature index shall be equal or greater than 280ºC. |

| 7) Oxygen Index | BS EN ISO 4589-2, BS 2863 These standards specify a test for measuring the minimum oxygen concentration to support candle like combustion of plastics. The oxygen index shall not be less than 30%. |

Color Code

Colour Scheme for Pairs

| Cabling

Element No. |

a-wire | b-wire | Cabling

Element No. |

a-wire | b-wire | ||

|---|---|---|---|---|---|---|---|

| 1 | WHITE | Blue | BLUE | 13 | BLACK | Green | GREEN |

| 2 | WHITE | Orange | ORANGE | 14 | BLACK | Brown | BROWN |

| 3 | WHITE | Green | GREEN | 15 | BLACK | Grey | GREY |

| 4 | WHITE | Brown | BROWN | 16 | YELLOW | Blue | BLUE |

| 5 | WHITE | Grey | GREY | 17 | YELLOW | Orange | ORANGE |

| 6 | RED | Blue | BLUE | 18 | YELLOW | Green | GREEN |

| 7 | RED | Orange | ORANGE | 19 | YELLOW | Brown | BROWN |

| 8 | RED | Green | GREEN | 20 | YELLOW | Grey | GREY |

| 9 | RED | Brown | BROWN | 21 | VIOLET | Blue | BLUE |

| 10 | RED | Grey | GREY | 22 | VIOLET | Orange | ORANGE |

| 11 | BLACK | Blue | BLUE | 23 | VIOLET | Green | GREEN |

| 12 | BLACK | Orange | ORANGE | 24 | VIOLET | Brown | BROWN |

| 25 | VIOLET | Grey | GREY | ||||

Note 1: Uppercase letters indicate the base, solid colour of insulation, and the lower case indicates ink bands applied onto the base colour.

Make Up & Unit Identification Colours – Unit

| Pair Size | 20 Pairs | 40 Pairs | 80 Pairs | 100 Pairs | 160 Pairs | 320 Pairs |

|---|---|---|---|---|---|---|

| Number of Units | ||||||

| Centre 1st Layer 2nd Layer |

1 | 4 X ½ | 1 | 1 | 4 X ½ | 1 |

| 6 X ½ | 8 X ½ | 6 | 5 | |||

| 10 | ||||||

| Unit No. | Colours of Unit Lappings | |||||

| 1 | ORANGE | ORANGE | ORANGE | ORANGE | ORANGE | ORANGE |

| 2 | GREEN | ORANGE | ORANGE | GREEN | ORANGE | |

| 3 | NATURAL | NATURAL | ORANGE | NATURAL | ||

| 4 | GREEN | NATURAL | NATURAL | NATURAL | ||

| 5 | GREEN | NATURAL | NATURAL | |||

| 6 | NATURAL | GREEN | ||||

| 7 | NATURAL | ORANGE | ||||

| 7 | GREEN | NATURAL | ||||

| 9-15 | NATURAL | |||||

| 16 | GREEN | |||||

Note 1: ½ refers to sub-units of 10 Pairs. Note 2: These cables include the single 1.38mm diameter insulated conductor.

Dimensions And Weight

| Cable Code | Number of Pairs |

Minimum Insulation

Thickness mm |

Pair Elements or Unit Size |

Minimum Sheath Thickness mm |

Maximum Overall Diameter mm |

Nominal Weight kg/km |

|---|---|---|---|---|---|---|

| 0.5mm Conductor, 0.95mm Insulated Wire-Layer | ||||||

| TP1600-2Y(St)H-2P05 | 2 | 0.15 | Prs1-2 | 0.6 | 4.5 | 23 |

| TP1600-2Y(St)H-3P05 | 3 | 0.15 | Prs1-3 | 0.6 | 5.0 | 35 |

| TP1600-2Y(St)H-4P05 | 4 | 0.15 | Prs1-4 | 0.6 | 5.8 | 40 |

| TP1600 -2Y(St)H-6P05 | 6 | 0.15 | Prs1-6 | 0.6 | 6.8 | 51 |

| TP1600-2Y(St)H-12P05 | 12 | 0.15 | Prs1-12 | 0.7 | 9.1 | 92 |

| TP1600-2Y(St)H-25P05 | 25 | 0.15 | Prs1-25 | 0.8 | 11.4 | 167 |

| 0.5mm Conductor, 0.95mm Insulated Wire-Unit | ||||||

| TP1600-2Y(St)H-(10P+E)05 | 10+E | 0.15 | 1/2X20 | 0.6 | 8.6 | 102 |

| TP1600-2Y(St)H-(20P+E)05 | 20+E | 0.15 | 20 | 0.7 | 12.0 | 157 |

| TP1600-2Y(St)H-(40P+E)05 | 40+E | 0.15 | 20 | 0.9 | 15.0 | 271 |

| TP1600-2Y(St)H-(50P+E)05 | 50+E | 0.15 | 20 | 1.0 | 18.0 | 341 |

| TP1600-2Y(St)H-(80P+E)05 | 80+E | 0.15 | 20 | 1.2 | 22.5 | 496 |

| TP1600-2Y(St)H-(100P+E)05 | 100+E | 0.15 | 20 | 1.5 | 27.0 | 633 |

| TP1600-2Y(St)H-(160P+E)05 | 160+E | 0.15 | 20 | 1.7 | 30.3 | 960 |

| TP1600-2Y(St)H-(320P+E)05 | 320+E | 0.15 | 20 | 2.2 | 39.5 | 1840 |

Note: The “E” in the table above indicates that the cable contains an earth-wire.