| Windmill Cables | |||

| EPR/HFXLEVA LSOH 0.6/1kV Torsion Resistant Power Cable | HFEPR/HFEVA 0.6/1kV LSOH Screened Torsion Resistant Power Cable | Al Conductor EPR/XLEVA 0.6/1kV LSOH Power Cable 90℃ | more |

Windmill Cables

Windmill Cables

H05VV5-F 300/500V

Application

These cables are used as supply or interconnecting cables for measuring, controlling and regulating for light and

medium mechanical stresses.

Standards

HD 21.13 S1

DIN VDE 0281 Part. 13/5/96

Construction

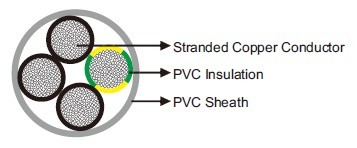

Conductor: Stranded bare copper, class 5/class 6 according to IEC 60228.

Insulation: PVC Type YI 4.

Sheath: PVC oil resistant Type YM 5.

Technical Data

Rated Voltage Uo/U (Um):300/500 V

Operating Temperatures:flexing: -15℃~+80℃; fixed: -40℃~+80℃

Minimum Bending Radius:flexing: 10×OD; fixed: 6×OD

Flame Retardant:IEC 60332-1

Oil Resistant:Yes

Ozone Resistant:Yes

Silicone Free:Yes

Dimensions and Weight

| Construction | Nominal Overall Diameter | Nominal Weight |

|---|---|---|

| No. of cores×mm² | mm | kg/km |

| 3G0.75 | 6.5 | 57 |

| 4G0.75 | 7.0 | 70 |

| 5G0.75 | 7.8 | 89 |

| 7G0.75 | 9.4 | 130 |

| 12G0.75 | 11.5 | 174 |

| 18G0.75 | 13.8 | 259 |

| 25G0.75 | 16.8 | 362 |

| 41G0.75 | 21.5 | 602 |

| 50G0.75 | 23.6 | 723 |

| 2×1 | 6.2 | 54 |

| 3G1 | 6.7 | 66 |

| 4G1 | 7.5 | 82 |

| 5G1 | 8.0 | 105 |

| 7G1 | 9.6 | 149 |

| 12G1 | 12.3 | 210 |

| 14G1 | 13.9 | 267 |

| 18G1 | 14.4 | 302 |

| 25G1 | 17.5 | 418 |

| 34G1 | 21.4 | 622 |

| 2×1.5 | 7.7 | 75 |

| 3G1.5 | 7.9 | 93 |

| 4G1.5 | 8.9 | 117 |

| 5G1.5 | 10.3 | 143 |

| 7G1.5 | 11.9 | 220 |

| 12G1.5 | 14.3 | 292 |

| 18G1.5 | 17.2 | 435 |

| 25G1.5 | 21.2 | 620 |

| 34G1.5 | 24.5 | 842 |

| 50G1.5 | 30.3 | 1305 |

| 3G2.5 | 9.4 | 144 |

| 4G2.5 | 10.8 | 180 |

| 5G2.5 | 11.8 | 229 |

| 7G2.5 | 14.0 | 300 |

| 12G2.5 | 17.3 | 453 |

| 18G2.5 | 20.5 | 684 |

| 25G2.5 | 25.5 | 943 |

G: with yellow/green earth core

×: without yellow/green earth core