| Windmill Cables | |||

| EPR/HFXLEVA LSOH 0.6/1kV Torsion Resistant Power Cable | HFEPR/HFEVA 0.6/1kV LSOH Screened Torsion Resistant Power Cable | Al Conductor EPR/XLEVA 0.6/1kV LSOH Power Cable 90℃ | more |

Windmill Cables

Windmill Cables

YCY 0.6/1kV UL/CSA

Application

These screened cables are designed for flexible use for medium mechanical stresses as measuring and control

cables in tool machines, conveyor belts, production lines; for plant installations, air conditioning, in steel

production plants and rolling mills, suitable for dry, moist and wet rooms as well as outside (fixed installation) .

Standards

VDE 0276 part 627

DIN VDE 0281 part 13

UL 758

IEC 60502

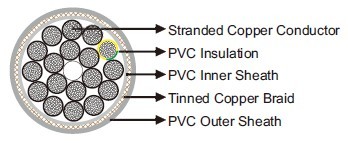

Construction

Conductor: Stranded bare copper, class 5 according to DIN VDE 0295/IEC60228.

Insulation: PVC type TI2 according to DIN VDE 0281 part 1, class 43 UL-Std. 1581.

Inner Sheath: PVC type TM 2 according to DIN VDE 0281 part 1, class 43 UL-Std. 1581.

Screen: Tinned copper braid.

Outer Sheath: PVC type TM 2 according to DIN VDE 0281 part 1, class 43 UL-Std. 1581.

Technical Data

Rated Voltage Uo/U (Um):600/1000V

Operating Temperatures:flexing: -5℃~+80℃; fixed: -40℃~+90℃

Minimum Bending Radius:flexing: 10×OD; fixed: 5×OD

Flame Retardant:VDE 0482-332-1-2/DIN EN 60332-1-2/IEC 60332-1/VW 1/FT1

Oil Resistant:Yes

Silicone Free:Yes

UV Resistant:Yes

Dimensions and Weight

| Construction | Nominal Overall Diameter | Nominal Weight |

|---|---|---|

| No. of cores×mm² | mm | kg/km |

| 2×0.5 | 8.3 | 129 |

| 3G0.5 | 8.6 | 150 |

| 4G0.5 | 9.4 | 170 |

| 5G0.5 | 10.1 | 199 |

| 7G0.5 | 12.1 | 235 |

| 12G0.5 | 14.7 | 320 |

| 18G0.5 | 17.3 | 428 |

| 25G0.5 | 20.6 | 503 |

| 2×0.75 | 8.7 | 143 |

| 3G0.75 | 9.0 | 155 |

| 4G0.75 | 9.9 | 190 |

| 5G0.75 | 10.8 | 228 |

| 7G0.75 | 13.0 | 323 |

| 12G0.75 | 15.8 | 410 |

| 18G0.75 | 17.9 | 560 |

| 25G0.75 | 22.8 | 730 |

| 2×1 | 9.4 | 150 |

| 3G1 | 9.8 | 163 |

| 4G1 | 10.8 | 200 |

| 5G1 | 12.1 | 239 |

| 7G1 | 14.5 | 289 |

| 12G1 | 17.4 | 464 |

| 18G1 | 20.7 | 628 |

| 25G1 | 24.8 | 855 |

| 2×1.5 | 10.2 | 162 |

| 3G1.5 | 10.9 | 187 |

| 4G1.5 | 12.2 | 240 |

| 5G1.5 | 13.3 | 289 |

| 7G1.5 | 16.0 | 383 |

| 12G1.5 | 19.6 | 592 |

| 18G1.5 | 23.4 | 806 |

| 25G1.5 | 28.2 | 1241 |

| 2×2.5 | 11.5 | 272 |

| 3G2.5 | 12.2 | 298 |

| 4G2.5 | 13.4 | 345 |

| 5G2.5 | 14.9 | 427 |

| 7G2.5 | 17.9 | 561 |

| 12G2.5 | 21.9 | 857 |

| 18G2.5 | 26.1 | 1355 |

| 25G2.5 | 31.9 | 1995 |

| 2×4 | 14.3 | 306 |

| 3G4 | 15.1 | 391 |

| 4G4 | 16.7 | 527 |

| 5G4 | 18.6 | 700 |

| 7G4 | 20.0 | 920 |

| 3G6 | 17.0 | 629 |

| 4G6 | 18.7 | 731 |

| 5G6 | 20.7 | 1105 |

| 7G6 | 23.0 | 1465 |

| 3G10 | 19.6 | 1125 |

| 4G10 | 21.9 | 1345 |

| 5G10 | 24.1 | 1635 |

| 7G10 | 26.8 | 2210 |

| 3G16 | 23.5 | 1395 |

| 4G16 | 26.4 | 1870 |

| 5G16 | 28.8 | 2720 |

| 7G16 | 31.9 | 3213 |

| 3G25 | 28.0 | 2465 |

| 4G25 | 32.5 | 2750 |

| 5G25 | 35.7 | 3490 |

| 7G25 | 39.0 | 4980 |

G: with green-yellow earth core

×: without green-yellow earth core