| Industrial Cables | |||

| American | French | German | Harmonized | Italian | JIS | Spanish |

Industrial Cables-British Standard

Industrial Cables-British Standard

6491B to BS 7211 (New BS EN 50525-3-41)

Application and Description

6491B to BS 7211 (New BS EN 50525-3-41) cables are designed for fixed wiring purposes in domestic and

industrial power/lighting applications. They can be used in trunking or conduit, or may be surface mounted when

used for earthing. and 6491B to BS 7211 (New BS EN 50525-3-41) cables are generally in areas (such as public

and government buildings) where smoke and toxic fumes may cause a threat to life and equipment. 6491B to BS

7211 (New BS EN 50525-3-41) cables produce no corrosive gasses when burnt and which is particularly

important where electronic equipment is installed. 6491B is equivalent to harmonized code H07Z-U/ H07Z-

R/H07Z-K.

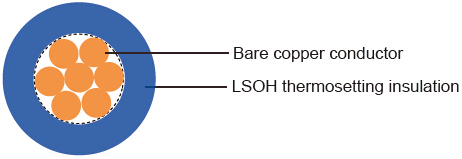

Cable Construction

-

Bare copper made of solid/strands conductor

Solid to BS 6360 CL-1 or IEC 60228 CL-1(H07Z-U)

Stranding to BS 6360 CL-2 or IEC 60228 CL-2(H07Z-R)

Stranding to BS 6360 CL-5 or IEC 60228 CL-5(H07Z-K)

LSOH thermosetting core insulation type EI5

Core Identification

Black, Blue, Green/Yellow, Red, Yellow, White, Violet, Brown, Grey, Orange, Pink

Technical Characteristics

-

Working voltage: 450/750 volts

-

Test voltage: 2500 volts

Minimum bending radius:

-

up to 10 mm² - 3xoverall diameter,

above 25 mm² - 6xoverall diameter

-

Operating temperature: +0º C to +90º C

Short circuit temperature: +250º C

Insulation resistance: 10 MΩxkm

Halogen free acc. to EN 50267-2-1 / IEC 60754-1

Smoke density acc. to EN 50268-2 / IEC 61034-2

Corrosivity of gases acc. to EN 50267-2-2, IEC 60754-2

Flame retardancy acc. to EN 50265-2-1, IEC 60332-1

Cable Parameter

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/km |

Nominal Weight kg/km |

|---|---|---|---|---|---|

| 16(solid) | 1x1.5 | 0,7 | 2.8 | 14.4 | 20 |

| 14(solid) | 1x2.5 | 0,8 | 3.3 | 24 | 30 |

| 12(solid) | 1x4 | 0,8 | 3.8 | 38 | 45 |

| 10(solid) | 1x6 | 0,8 | 4.3 | 58 | 65 |

| 8(solid) | 1x10 | 1,0 | 5.5 | 96 | 105 |

| 16(7/24) | 1x1.5 | 0.7 | 3.0 | 14.4 | 21 |

| 14(7/22) | 1x2.5 | 0.8 | 3.6 | 24 | 33 |

| 12(7/20) | 1x4 | 0.8 | 4.1 | 39 | 49 |

| 10(7/18) | 1x6 | 0.8 | 4.7 | 58 | 71 |

| 8(7/16) | 1x10 | 1 | 6 | 96 | 114 |

| 6(7/14) | 1x16 | 1 | 6.8 | 154 | 172 |

| 4(7/12) | 1x25 | 1.2 | 8.4 | 240 | 265 |

| 2(7/10) | 1x35 | 1.2 | 9.3 | 336 | 360 |

| 1(19/13) | 1x50 | 1.4 | 10.9 | 480 | 487 |

| 2/0(19/11) | 1x70 | 1.4 | 12.6 | 672 | 683 |

| 3/0(19/10) | 1x95 | 1.6 | 14.7 | 912 | 946 |

| 4/0(37/12) | 1x120 | 1.6 | 16 | 1152 | 1174 |

| 300MCM(37/11) | 1x150 | 1.8 | 17.9 | 1440 | 1448 |

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/km |

Nominal Weight kg/km |

|---|---|---|---|---|---|

| 350MCM(37/10) | 1x185 | 2.0 | 20.0 | 1776 | 1820 |

| 500MCM(61/11) | 1x240 | 2.2 | 22.7 | 2304 | 2371 |

| -(61/10) | 1x300 | 2.4 | 25.4 | 2980 | 3050 |

| -(61/9) | 1x400 | 2.6 | 28.8 | 3765 | 3842 |

| -(61/8) | 1x500 | 2.8 | 32.8 | 4725 | 4900 |

| -(127/10) | 1x630 | 2.8 | 36.5 | 6205 | 6334 |

| 16(30/30) | 1 x 1.5 | 0,7 | 3.5 | 14.4 | 24 |

| 14(50/30) | 1 x 2.5 | 0,8 | 4 | 24 | 35 |

| 12(56/28) | 1 x 4 | 0,8 | 4.8 | 38 | 51 |

| 10(84/28) | 1 x 6 | 0,8 | 6 | 58 | 71 |

| 8(80/26) | 1 x 10 | 1,0 | 6.7 | 96 | 118 |

| 6(128/26) | 1 x 16 | 1,0 | 8.2 | 154 | 180 |

| 4(200/26) | 1 x 25 | 1,2 | 10.2 | 240 | 278 |

| 2(280/26) | 1 x 35 | 1,2 | 11.5 | 336 | 375 |

| 1(400/26) | 1 x 50 | 1,4 | 13.6 | 480 | 560 |

| 2/0(356/24) | 1 x 70 | 1,4 | 16 | 672 | 780 |

| 3/0(485/24) | 1 x 95 | 1,6 | 18.4 | 912 | 952 |

| 4/0(614/24) | 1 x 120 | 1,6 | 20.3 | 1152 | 1200 |

| 300 MCM (765/24) | 1 x 150 | 1,8 | 22.7 | 1440 | 1505 |

| 350 MCM (944/24) | 1 x 185 | 2,0 | 25.3 | 1776 | 1845 |

| 500MCM(1225/24) | 1 x 240 | 2,2 | 28.3 | 2304 | 2400 |