| Motor Connecting Cables | |||

| 2YSLCY-JB/2YSLCYK-JB | 9YSLCY-JB | PENDANT CABLE |

Liquid-cooled EV charging Cable

Liquid-cooled EV charging Cable

Oil-cooled Cables

APPLICATION

The application mode of the cables is mainly used to connect electric vehicle charging devices to the charging

infrastructure, thus providing fast power transmission to electric vehicles, and equipped with a certain number of

signal and control lines to ensure accurate control and safe and error-free operation of the entire charging

process.

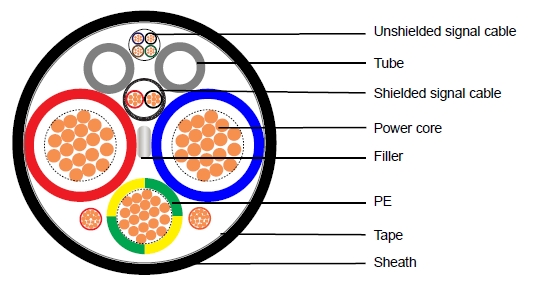

The cable structure is mainly composed of the main core of power supply, ground wire, signal wire or shield wire

set, return pipe, filler and reinforcing rope combination. DC+ and DC- conductors are immersed in the cooling

medium to take away heat through the medium and form a cooling circuit through the circulation of the return

pipe, which eventually carries a larger current with a smaller conductor cross-section to achieve the effect of

high-power fast charging. The cable use scenario is generally used in centralized charging stations, large

parking lots, hotels, garages and other areas.

STANDARDS

Basic design to IEC62893-4-2

CABLE CONSTRUCTION

Conductor: Bare copper or tinned copper, class 5 to IEC60228.

Power cores 16mm2 to 150mm2

Control or pilot cores min. 0.5mm2

Optional PE conductor min. 25mm2

Optional auxiliary power cores 2.5mm2 to 6mm2

Insulation: Irradiation cross-linked polyolefin.

Screen(optional): Braided copper wire. Tube: Irradiation cross-linked polyolefin. Filler: PP hemp or cotton yarn.

Tape: Non-woven fabric.

Sheath: TPU, Black,other colours can be offered upon request.

TECHNICAL CHARACTERISTICS

Temperature range: - 40º C to + 90º C

Rated voltage: AC 600V/1000V ; DC 1500V

Flame resistant: According to EN 60332-1-2

Minimum bending radius: 6×OD

Dielectric voltage: 3.5kVac/15min.No Breakdown

Oil resistant: IRM902,100°C/168h Tensile and Elongation≥60%

Cold bending: -40°C/4h No cracks Hot shock: 150°C/1h No cracks

Crush resistant: > 11KN

Weather resistant: 720min a xenon arc weatherometer, No cracks

CONSTRUCTION PARAMETERS

No.of Cores×Cross section |

Nominal Thickness of Insulation |

Nominal Thickness of Sheath |

Maximum Overall Diameter |

Minimum Insulation Resistance at 90 °C e |

|---|---|---|---|---|

mm² |

mm |

mm |

mm |

MΩ · km |

2×16 |

0.8 |

2.4 |

|

0.0044 |

2×25 |

1.0 |

2.8 |

|

0.0043 |

2×35 |

1.0 |

3.2 |

Design |

0.0037 |

2×50 |

1.1 |

3.6 |

structures |

0.0034 |

according to |

||||

2×70 |

1.2 |

4.0 |

standards |

0.0031 |

or customer |

||||

2×95 |

1.2 |

4.4 |

requirements |

0.0028 |

2×120 |

1.3 |

4.8 |

|

0.0027 |

2×150 |

1.5 |

5.3 |

|

0.0028 |

Note: 1. Signal line range n = 0-10

The number of reflux tubes according to customer requirements.

Cooling medium is defined by the client.