|

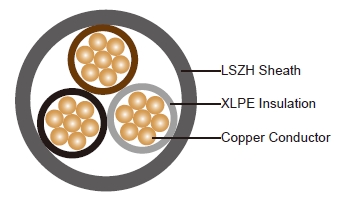

Three-core 600/1000V XLPE Insulation, LSZH Sheath Cables to BS 8573

Application:

BS 8573 XLPE insulated and LSZH sheathed cables are generally used for fixed installation. Suitable for building wiring, especially in areas where smoke and fume emissions may cause a potential threat to life but not for burial in the ground, either directly or in ducts.

Standard:

Basic design to BS 8573:2012

Fire Performance:

-

Flame Retardance (Single Vertical Wire Test) BS EN 60332-1-2:2004 Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) BS EN 60332-3-24:2009 (cat. C) Halogen Free BS EN 50267-2-1 Minimum Smoke Emission BS EN 61034-2 Spark Test BS EN 62230

Voltage Rating:

600/1000V

Construction:

Conductor: Annealed copper conductor, strand according to BS EN 60228 class 2.

Insulation: Thermosetting insulation XLPE Type GP8 according to BS 7655-1.3, XLPE Type GP6 according to BS 7655-1.2, or XLPE Type EI5 according to BS EN 50363-5.

Inner Covering option: The laid up cores may be coverd by an optional extrued inner covering or separating tape. It shall be possible to separate the cores easily.

outer Sheath: Thermoplastic LSZH type LTS 4 according to BS 7655-6.1.

outer Sheath option: UV resistance, hydrocarbon resistance, oil resistance, anti rodent and antitermite properties can be offered as option.

Color Code:

Insulation Colour: Brown, black and grey

Sheath Colour: Black, other colours can be offered upon request.

Physical And Thermal Properties:

Maximum temperature range during operation (XLPE): 90°C

Maximum short circuit temperature (5 Seconds): 250°C

Minimum bending radius:

Circular copper conductors(up to 25mm²): 4 x Overall Diameter

Circular copper conductors(above 25mm²): 6 x Overall Diameter

Shaped copper conductors: 8 x Overall Diameter

Construction Parameters:

-

Conductor Nominal Insulation Thickness Nominal Inner Covering

ThicknessNominal Sheath Thickness No. of

CoresxCross SectionClass of Conductor No.xmm² mm mm mm 3x1.5 2 0.7 0.4 1.8 3x2.5 2 0.7 0.4 1.8 3x4.0 2 0.7 0.4 1.8 3x6.0 2 0.7 0.4 1.8 3x10 2 0.7 0.6 1.8 3x16 2 0.7 0.6 1.8 3x25 2 0.9 0.8 1.8 3x35 2 0.9 0.8 1.8 3x50 2 1.0 1.0 1.8 3x70 2 1.1 1.2 1.9 3x95 2 1.1 1.2 2.0 3x120 2 1.2 1.2 2.1 3x25 2 0.9 0.6 1.8 3x35 2 0.9 0.8 1.8 3x50 2 1.0 0.8 1.8 3x70 2 1.1 1.0 1.9 3x95 2 1.1 1.2 2.0 3x120 2 1.2 1.2 2.1