|

Customized Products

Fire resistant RG59 b/U Coaxial Cables

RG59 B/U FR

Application:

The cables are designed for CCTV, security, smoke detection and evacuation monitoring applications, where continued functionality is required during a fire situation. Due to the zero halogen low smoke construction, this cable is ideal for use in public, commercial and industrial environments.

Standards:

Basic design to MIL-C-17

Fire Performance:

| Circuit Integrity | IEC 60331-23; BS 6387 CWZ; DIN VDE 0472-814(FE180); CEI 20-36/2-1; SS299-1; NBN C 30-004 (cat. F3); |

|---|---|

| System Circuit Integrity | DIN 4102-12, E30 depending on lay system |

| Flame Retardance (Single Vertical Wire Test) | EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1 ; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

| Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

| Halogen Free | IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1* |

| No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

| Minimum Smoke Emission | IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

| No Toxic gases | NES 02-713; NF C 20-454 |

note: asterisk * denotes superseded standard.

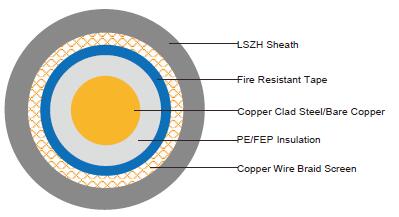

Cable Construction:

Conductors: Copper clad steel, solid according to IEC 60228 class 1.

insulation: PE wrapped with fire resistant silicone rubber compound type EI2 as per BS 7655-1.1 or fluoropolymer(FEP) compound.

binder: Glass tape

Overall screen: Plain copper wire braid

Outer sheath: Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1(Thermosetting LSZH compound type SW2-SW4 as per BS 7655-2.6 can be offered.). UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option.

Physical and Thermal Properties:

Temperature range during operation (fixed state): -30°C - +70°C

temperature range during installation (mobile state): -5ºC - +60ºC

Minimum bending radius: 8 x Overall Diameter

Electrical Properties:

| Impedance | 75±5Ω |

|---|---|

| Capacitance | 67 nF/km |

| Velocity ratio(%) | 66 |

| Insulation resistance | >2000 Mohm.Km |

| Shield coverage | 95% |

| DC resistance |

|

| Inner conductor | 158 Ω/km |

| Outer conductor | 9.0 Ω/km |

Attenuation:

| Frequency(MHz) | Attenuation (dB/100 m) | Attenuation (dB/100ft) |

|---|---|---|

50 |

7.4 |

2.26 |

100 |

10.7 |

3.26 |

200 |

15.7 |

4.79 |

400 |

22.7 |

6.92 |

500 |

25.7 |

7.84 |

600 |

28.7 |

8.75 |

860 |

34.8 |

10.61 |

1000 |

38.0 |

11.59 |

Return Loss:

| Frequency(MHz) | Return Loss (dB) |

|---|---|

30-300 MHz |

>31dB |

300-600 MHz |

>28dB |

600-900 MHz |

>24dB |

Construction Parameters:

| cable Code |

Conductor Diameter | Nominal Insulation Diameter | Nominal Screen No.x Diameter |

Nominal Overall Diameter | Approx. Weight |

|---|---|---|---|---|---|

| mm | mm | No. x mm | mm | kg/km | |

RG59 B/U FR |

0.58 ± 0.03 |

3.70 ± 0.10 m |

120 x 0.15 |

6.20 ± 0.10 |

60.3 |