TUNNEL CABLES |

||||||||||

TUNNEL CABLES

TUNNEL CABLES

(N)3GHSSYCY

Application

These cables are used for the connection of mobile operating equipments in mines and underground

excavations with hazardous environments. In stationary operation, e.g.highvoltage transformers in mining and

tunnelling.

STANDARDS

| construction | DIN VDE 0250-605 & IEC 60502-2 |

|---|---|

General Requirements |

DIN VDE 0250-1 |

Guide Use |

DIN VDE 0298-3 |

Electrical Tests |

DIN VDE 0472-501, 503, 508 |

Non-Electrical Tests |

DIN VDE 0472-401. 402,602,303, 615 |

Flame Retardant |

VDE 0482-332-1-2,DIN EN 60332-1-2,IEC 60332-1 |

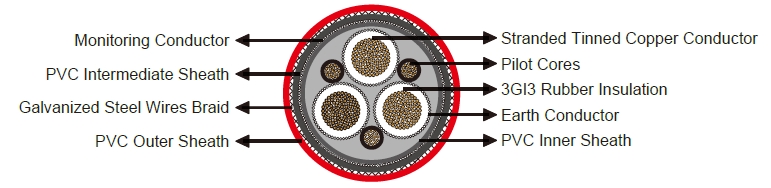

CABLE CONSTRUCTION

conductor |

Flexible electrolytic stranded tinned copper wire DIN VDE 0295 Class 5 |

|---|---|

Insulation |

|

Main Cores |

3Gl3 type EPR compound |

Pilot Control Cores |

3Gl3 type EPR compound |

Electrical Field Control |

Extruded inner and outer rubber semiconductive layer For 3.6/6 kV cables outer semiconductive layer only |

Protective Conductor |

Made of plain copper wires or copper wire braiding laid up concentrically around each main core |

Core Identification |

|

Main Cores |

Natural coloring, design acc to DIN VDE 0250 Part 1 |

Pilot Cores |

Black colored and number coded |

Lay Up |

Three main conductors laid-up with three pilot control cores in the outer interstice.Protective cores are concentricalty wrapped over insulation of power cores |

Inner Sheath |

YM5 type PVC compound |

Monitoring Conductor |

Semioonductive tape + overall concentric lay of copper wires and syntetic tape over wires |

Inner Sheath |

PVC compound type DMV6 acc. to DIN VDE 0276-603 |

Armour |

Galvanized steel wire braiding, coverage minimum 75% ST2 Type to IEC60502 |

Outer Sheath |

PVC compound type DMV6 acc. to DIN VDE 0276-603, Red or Black |

Technical Characteristics

Rated Voltage |

3.6/6 KV |

6/10 KV |

8.7/15KV |

12/20 KV |

18/30 KV |

|---|---|---|---|---|---|

AC Test Voltage |

11KV |

17KV |

24KV |

29KV |

43KV |

Max.Permissible Operating Voltage AC |

4.2/7.2KV |

6.9/12KV |

10.4/18KV |

13.9/24KV |

20.8/36 KV |

Max.Permissible Operating Voltage DC |

5.4/10.8 KV |

9/18 KV |

13.5/27 KV |

18/36 KV |

27/54 KV |

Min Bending Radius |

DIN VDE 0298-3 |

||||

Current Carrying Capacities |

DIN VDE 0298-4 |

||||

Working Temperature |

|||||

Fixed |

-40°C- +80°C |

||||

Mobile |

+5°C- +80°C |

||||

Max.Tensile Load Of cable |

20N/mm² |

||||

max.torsion |

25°/m |

||||

Trawl Speed For Tunnelling App |

Max.30 m/min |

||||

Minimum Distarce For Change Of Direction |

20×D |

||||

Dimensions And Weight

3.6/6 KV

| Cross Section (mm²) | Overall Diameter |

conductor Resistance at 20°c |

Appro. Weight (kg/km) |

|---|---|---|---|

3x25+3x16/3E+3x2.5ST+ÜL |

47.0-51.0 |

0.780 |

3600 |

3x35+3x16/3E+3x2.5ST+ÜL |

49.0-54.0 |

0.554 |

4170 |

3x50+3x25/3E+3x2.5ST+ÜL |

52.0-57.8 |

0.386 |

4850 |

3x70+3x35/3E+3x2.5ST+ÜL |

56.1-61.2 |

0.272 |

5900 |

3x95+3x50/3E+3x2.5ST+ÜL |

60.3-66.2 |

0.206 |

7044 |

3x120+3x70/3E+3x2.5ST+ÜL |

63.8-70.2 |

0.161 |

8620 |

3x150+3x70/3E+3x2.5ST+ÜL |

66.0-72.0 |

0.129 |

9860 |

3x185+3x95/3E+3x2.5ST+ÜL |

70.0-74.0 |

0.106 |

11300 |

6/10 KV

| Cross Section (mm²) | Overall Diameter |

conductor Resistance at 20°c |

Appro. Weight (kg/km) |

|---|---|---|---|

3x25+3x16/3E+3x2.5ST+ÜL |

54.0-57.0 |

0.780 |

4200 |

3x35+3x16/3E+3x2.5ST+ÜL |

57.1-60.2 |

0.554 |

4650 |

3x50+3x25/3E+3x2.5ST+ÜL |

60.4-63.6 |

0.386 |

5380 |

3x70+3x35/3E+3x2.5ST+ÜL |

65.2-68.8 |

0.272 |

6450 |

3x95+3x50/3E+3x2.5ST+ÜL |

68.0-71.9 |

0.206 |

7700 |

3x120+3x70/3E+3x2.5ST+ÜL |

70.1-76.1 |

0.161 |

9260 |

3x150+3x70/3E+3x2.5ST+ÜL |

73.0-78.0 |

0.129 |

10840 |

3x185+3x95/3E+3x2.5ST+ÜL |

74.0-79.2 |

0.106 |

12400 |

8.7/15KV

| Cross Section (mm²) | Overall Diameter |

conductor Resistance at 20°c |

Appro. Weight (kg/km) |

|---|---|---|---|

3x25+3x16/3E+3x2.5ST+ÜL |

58.0-62.0 |

0.780 |

4530 |

3x35+3x16/3E+3x2.5ST+ÜL |

61.0-65.0 |

0.554 |

5100 |

3x50+3x25/3E+3x2.5ST+ÜL |

64.7-68.7 |

0.386 |

5840 |

3x70+3x35/3E+3x2.5ST+ÜL |

67.9-71.9 |

0.272 |

7840 |

3x95+3x50/3E+3x2.5ST+ÜL |

72.4-76.4 |

0.206 |

9210 |

12/20 KV

| Cross Section (mm²) | Overall Diameter |

conductor Resistance at 20°c |

Appro. Weight (kg/km) |

|---|---|---|---|

3x25+3x16/3E+3x2.5ST+ÜL |

62.3-66.3 |

0.780 |

4920 |

3x35+3x16/3E+3x2.5ST+ÜL |

65.3-69.3 |

0.554 |

5400 |

3x50+3x25/3E+3x2.5ST+ÜL |

69.0-73.0 |

0.386 |

6200 |

3x70+3x35/3E+3x2.5ST+ÜL |

72.2-76.2 |

0.272 |

8240 |

3x95+3x50/3E+3x2.5ST+ÜL |

76.8-80.8 |

0.206 |

9610 |

3x120+3x70/3E+3x2.5ST+ÜL |

81.0-84.0 |

0.161 |

11260 |

3x150+3x70/3E+3x2.5ST+ÜL |

84.5-88.7 |

0.129 |

13840 |

3x185+3x95/3E+3x2.5ST+ÜL |

89.0-93.5 |

0.106 |

15400 |