TUNNEL CABLES |

||||||||||

TUNNEL CABLES

TUNNEL CABLES

NTSCGEWöU

Application

For the connection of electrical equipment large material handling machines such as excavators, cranes,

dumpers in mining and tunneling applications. The flexible cable design allows for movement of the equipment

during operation.

STANDARDS

| construction | DIN VDE 0250-813 |

|---|---|

General Requirements |

DIN VDE 0250-1 |

Guide Use |

DIN VDE 0298-3 |

Electrical Tests |

DIN VDE 0472-501, 503, 508 |

Non-Electrical Tests |

DIN VDE 0472-401. 402,602,303, 615 |

Under Fire Condition Tests |

DIN VDE 0472-803, 804 |

Flame Retardant |

VDE 0482-332-1-2,DIN EN 60332-1-2,IEC 60332-1 |

Oil Resistant |

HD/EN/IEC 60811-2-1.,DIN VDE0473-811-2-1 |

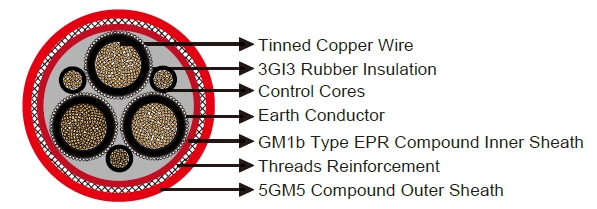

CABLE CONSTRUCTION

conductor |

Electrolytic, stranded, tinned copper wire DIN VDE 0295 Class 5 |

|---|---|

Insulation |

3Gl3 type EPR compound |

Electrical Field Control |

Inner and Outer semiconductive layer of semiconductive rubber |

Protective-Earth conductor |

Tinned Copper conductor with semiconductive layer |

Lay Up |

Three main conductors laid-up with three control cores in the outer interstice |

Inner Sheath |

GM1b Type EPR Compound |

Reinforcement |

Embedded braid made of anti torsion synthetic threads |

Outer Sheath |

5GM5 Type elastomer compound. Red |

Technical Characteristics

| Rated Voltage | 3.6/6 KV |

6/10 KV |

8.7/15KV |

12/20 KV |

18/30 KV |

|---|---|---|---|---|---|

AC Test Voltage |

11KV |

17KV |

24KV |

29KV |

43KV |

Max.Permissible Operating Voltage AC |

4.2/7.2KV |

6.9/12 KV |

10.4/18KV |

13.9/24 KV |

20.8/36 KV |

Min Bending Radius |

VDE 0298-3 Tab 3 |

||||

Current Carrying Capacities |

VDE 0298-4 |

||||

Working Temperature |

|||||

Fixed |

-40°C-+80°C |

||||

Mobile |

-25°C-+80°C |

||||

Max.Tensile Load Of cable |

15N/mm² |

||||

max.torsion |

25°/m |

||||

Trawl Speed For Tunnelling App |

Max.30 m/min |

||||

Minimum Distarce For Change |

20×D |

||||

Dimensions And Weight

3.6/6 KV

| Cross Section (mm²) |

Overall Diameter |

Appro. Weight (kg/km) |

|---|---|---|

3x25 + 3x25/3 |

41.8-45.0 |

2530 |

3x35 + 3x25/3 |

44.2-48.9 |

2900 |

3x50 + 3x25/3 |

48.5-51.4 |

3600 |

3x70 + 3x35/3 |

52.6-55.6 |

4400 |

3x95 + 3x50/3 |

55.7-58.8 |

5630 |

3x120 + 3x70/3 |

59.6-65.9 |

6200 |

6/10 KV

| Cross Section (mm²) |

Overall Diameter |

Appro. Weight (kg/km) |

|---|---|---|

3x25 + 3x25/3 |

43.6-48.1 |

2600 |

3x35 + 3x25/3 |

45.6-50.4 |

2980 |

3x50 + 3x25/3 |

48.3-51.4 |

3720 |

3x70 + 3x35/3 |

53.4-59.1 |

4510 |

3x95 + 3x50/3 |

57.1-63.2 |

5720 |

3x120 + 3x70/3 |

63.0-69.7 |

6300 |

8.7/15 KV

| Cross Section (mm²) |

Overall Diameter |

Appro. Weight (kg/km) |

|---|---|---|

3x25 + 3x25/3 |

48.1-53.2 |

3675 |

3x35 + 3x25/3 |

51.8-57.3 |

4415 |

3x50 + 3x25/3 |

55.5-61.4 |

5135 |

3x70 + 3x35/3 |

58.0-64.1 |

6005 |

3x95 + 3x50/3 |

63.4-70.1 |

7200 |

3x120 + 3x70/3 |

67.5-74.6 |

8700 |

12/20 KV

| Cross Section (mm²) |

Overall Diameter |

Appro. Weight (kg/km) |

|---|---|---|

3x25 + 3x25/3 |

51.1-55.3 |

4460 |

3x35 + 3x25/3 |

54.4-58.2 |

4990 |

3x50 + 3x25/3 |

59.4-63.6 |

5740 |

3x70 + 3x35/3 |

64.2-68.4 |

6950 |

3x95 + 3x50/3 |

69.6-73.8 |

7870 |

3x120 + 3x70/3 |

73.6-77.8 |

9425 |

18/30 KV

| Cross Section (mm²) |

Overall Diameter |

Appro. Weight (kg/km) |

|---|---|---|

3x25 + 3x25/3 |

66.0-72.8 |

6360 |

3x35 + 3x25/3 |

68.0-75.0 |

6925 |

3x50 + 3x25/3 |

71.6-79.1 |

7800 |

3x70 + 3x35/3 |

75.8-83.7 |

9140 |

3x95 + 3x50/3 |

79.4-87.7 |

10100 |

3x120 + 3x70/3 |

85.3-94.2 |

12260 |

20/35 KV

| Cross Section (mm²) |

Overall Diameter |

Appro. Weight (kg/km) |

|---|---|---|

3x35 + 3x25/3 |

75.7-83.6 |

8400 |

3x50 + 3x25/3 |

79.5-87.8 |

9360 |

3x70 + 3x35/3 |

82.0-90.6 |

10400 |

3x95 + 3x50/3 |

87.3-96.4 |

11770 |

3x120 + 3x70/3 |

91.4-101.1 |

13680 |