TUNNEL CABLES |

||||||||||

TUNNEL CABLES

TUNNEL CABLES

(N)SSHöU

Application

For use in mines, quarries, industrial areas, construction sites agricultural operations and as trailing cable. The

cables are also suitable for fixed application as power supply cable for underground mining and open-cast

mining applications, for tunneling applications and similar applications.

STANDARDS

| construction | DIN VDE 0250-812 |

|---|---|

General Requirements |

DIN VDE 0250-1 |

Guide Use |

DIN VDE 0298-3 |

Electrical Tests |

DIN VDE 0472-501, 503, 508 |

Non-Electrical Tests |

DIN VDE 0472-401. 402,602,303, 615 |

Under Fire Condition Tests |

DIN VDE 0472-803, 804 |

Flame Retardant |

VDE 0482-332-1-2,DIN EN 60332-1-2,IEC 60332-1 |

Oil Resistant |

HD/EN/IEC 60811-2-1.,DIN VDE0473-811-2-1 |

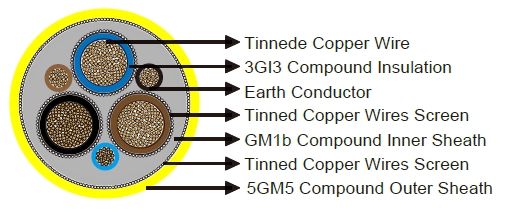

CABLE CONSTRUCTION

conductor |

Electrolytic, stranded, tinned copper wire DIN VDE 0295 Class 5 |

|---|---|

Insulation |

All cores are insulated with 3Gl3 compound (acc.to DIN VDE 0207 Part 20) |

Screen |

3/E coded types has individual screens made by laying up tinned copper wires over the insulation. |

Lay Up |

All cores are laid up in contact with each other and intersititial |

Inner Sheath |

Special elastomeric compound GM1b (acc. to DIN VDE 02(17 Part |

Screen |

Overall-screen made of tinned copper wires in between inner and outer sheaths |

Outer Sheath |

Heavy-duty elastomer outer sheath 5GM5(acc.to DIN VDE 0207 Part 21) |

Technical Characteristics

| Rated Voltage | 0.6 / 1 KV |

|---|---|

Max.Permissible Operating Voltage AC |

0.7 / 1.2 KV |

Max.Permissible Operating Voltage DC |

0.9 / 1.8 KV |

AC Test Voltage |

3KV |

Min Bending Radius Current Carrying |

VDE 0298-3 Tab 3 |

Current Carrying Capacities |

VDE 0298-4 |

Working Temperature |

|

Fixed |

-40°C-+80°C |

Mobile |

-25°C-+80°C |

Max.Tensile Load Of cable |

15N/mm² |

Dimensions And Weight

| Cross Section (mm²) |

Overall Diameter |

Appro. Weight (kg/km) |

|---|---|---|

1×16 |

11-14 |

250 |

1×25 |

13-18 |

400 |

1×35 |

14-18 |

500 |

1×50 |

16-19 |

700 |

1×70 |

18-21 |

950 |

1×95 |

20-24 |

1200 |

1×120 |

23-26 |

1500 |

1×150 |

25-28 |

1800 |

1×185 |

28-31 |

2300 |

1×240 |

32-36 |

3000 |

3×1.5 |

11-14 |

250 |

3×2.5 |

13-16 |

300 |

4×2.5 |

15-18 |

400 |

4×4 |

17-20 |

500 |

4×6 |

19-22 |

600 |

4×10 |

23-26 |

950 |

4×16 |

27-30 |

1400 |

4×25 |

33-37 |

2100 |

4×35 |

35-39 |

2600 |

4×50 |

42-46 |

3700 |

4×70 |

45-49 |

4600 |

4×95 |

53-57 |

6300 |

4×120 |

59-63 |

7800 |

5×4 |

19-22 |

600 |

5×6 |

21-24 |

750 |

7×2.5 |

18-21 |

600 |

12×2.5 |

23-26 |

850 |

19×2.5 |

28-32 |

1200 |

3x2.5+3x2.5/3E |

16-19 |

350 |

3x4+3x4/3E |

19-22 |

500 |

3x6+3x6/3E |

20-23 |

600 |

3x10+3x10/3E |

24-28 |

950 |

3x16+3x16/3E |

27-30 |

1200 |

3x 25+3x16/3E |

29-33 |

1800 |

3x35+3xl6/3E |

34-38 |

2300 |

3x50+3x25/3E |

40-44 |

3300 |

3x70+3x35/3E |

44-48 |

4100 |

3x95+3x50/3E |

50-55 |

5500 |

3x120+3x70/3E |

55-60 |

6800 |

3x150+3x70/3E |

59-64 |

8000 |

3x2.5+3x2.5/3E+3x1.5St |

18-20 |

500 |

3x4+3x4/3E+3x1.5St |

19-22 |

550 |

3x6+3x6/3E+3x1.5St |

20-24 |

650 |

3x10+3x10/3E+3x2.5St |

24-28 |

1000 |

3x16+3x16/3E+3x2.5St |

27-30 |

1300 |

3x25+3x16/3E+3x2.5St |

30-34 |

1800 |

3x35+3x16/3E+3x2.5St |

34-38 |

2400 |

3x50+3 x25/3E+3x2.5St |

40-44 |

3200 |

3x70+3x35/3E+3x2.5St |

44-48 |

4200 |

3x95+3x50/3E+3X2.5St |

48-53 |

5600 |

3x120+3x70/3E+3x2.5St |

51-56 |

6800 |

3x150+3x70/3E+3x2.5St |

59-64 |

8100 |

3x2.5/2.5 kon |

15-18 |

350 |

5x2.5/2.5 kon |

19-23 |

500 |

5x4/4 kon |

20-23 |

650 |

5x6/6 kon |

21-24 |

800 |

10x1.5 /1.5 kon |

20-24 |

800 |

10x2.5/2.5 kon |

26-29 |

1100 |