TUNNEL CABLES |

||||||||||

TUNNEL CABLES

TUNNEL CABLES

NSHCGEöU KON+ST+UL

Application

It is used for connection of mobile machines with very high mechanical load, especially in mines for coal cutting

and loading machines as well as for supplying appliances and auxiliary and auxiliary electrical circuits. Concentric

phase monitoring screen and overall concentric earth conductor facilitate in connection with a suitable

monitoring equipment monitoring of the cable from standpoint of insulation faults and damages that are caused

by external effects.

STANDARDS

| construction | DIN VDE 0250-812 |

|---|---|

General Requirements |

DIN VDE 0250-1 |

Guide Use |

DIN VDE 0298-3 |

Electrical Tests |

DIN VDE 0472-501, 503, 508 |

Non-Electrical Tests |

DIN VDE 0472-401. 402,602,303, 615 |

Under Fire Condition Tests |

DIN VDE 0472-803, 804 |

Flame Retardant |

VDE 0482-332-1-2,DIN EN 60332-1-2,IEC 60332-1 |

Oil Resistant |

HD/EN/IEC 60811-2-1.,DIN VDE0473-811-2-1 |

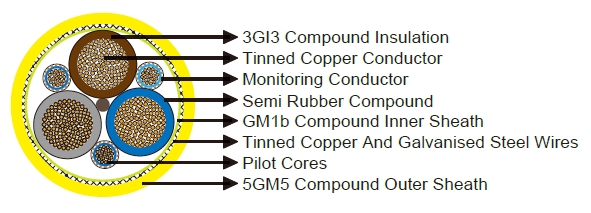

CABLE CONSTRUCTION

Power Cores |

|

|---|---|

conductor |

Tinned copper conductor DIN VDE 0295 class 5 |

Insulation |

Based on 3Gl3-EPR rubber and semi rubber compound |

Control Cores+Monitoring Pe Core(S) |

|

conductor |

Tinned copper conductor DIN VDE 0295 class 5 |

Insulation |

3Gl3 type EPR compound and semi conductive rubber compound |

Lay Up |

Three power cores laid up with the protective earth conductors split into three in the outer interstices. If there are 3 control cores. the monitoring core is concentrically wrapped over insulation of control cores. |

Inner Sheath |

GM1b type EPR compound |

Screen |

Flexible- pliable armour in helix of tinned copper and galvanised steel wires. |

Outer Sheath |

Heavy-duty elastomer 5GM5 type rubber compound Yellow or |

Technical Characteristics

| Rated Voltage | 0.6 / 1 KV |

|---|---|

Max.Permissible Operating Voltage AC |

0.7 / 1.2 KV |

Max.Permissible Operating Voltage DC |

0.9 / 1.8 KV |

AC Test Voltage |

3KV |

AC Test Voltage(For control cores) |

2KV |

Min. 011otance with S-Type Directional Changes |

20×D |

Current Carrying Capacities |

According to DIN VDE 0298-4 |

Working Temperature |

|

Fixed |

-40°C-+80°C |

Mobile |

-25°C-+80°C |

Max.Tensile Load Of cable |

15N/mm² |

Dimensions And Weight

| Cross Section (mm²) |

Overall Diameter |

Appro. Weight (kg/km) |

|---|---|---|

3×16/16 KON + (2x1.5 St+1.5 ÜL) |

35-38 |

2150 |

3×25/16 KON + (2x1.5 St+1.5 ÜL) |

41-46 |

3000 |

3×35/16 KON + (2x1.5 St+1.5 ÜL) |

42-47 |

3400 |

3×70/35 KON + (2x1.5 St+1.5 ÜL) |

46-51 |

4300 |

3×70/35 KON + (2x1.5 St+1.5 ÜL) |

52-56 |

5600 |

3×95/50 KON + (2x1.5 St+1.5 ÜL) |

58-62 |

7100 |

3x25/16 KON+3x(1.5 ST KON/1.5 ÜL KON) |

42-46 |

3130 |

3x35/16 KON+3x(1.5 ST KON/1.5 ÜL KON) |

43-47 |

3610 |

3x50/35 KON+3x(1.5 ST KON/1.5 ÜL KON) |

49-53 |

4580 |

3x70/35 KON+3x(1.5 ST KON/1.5 ÜL KON) |

52-56 |

5920 |

3x95/50 KON+3x(1.5 ST KON/1.5 ÜL KON) |

60-64 |

7400 |